About Us

Durmapress specializes in designing, manufacturing, and selling various metal processing equipment, including bending machines, shears, punches, and laser cutting machines. The company was founded in 2014, with years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

European Technical Background

The bending follower technology for press brakes originated in Europe. The concept was first introduced around 1990, and gradually matured between 2000 and 2005. During this period, leading press brake manufacturers such as TRUMPF (Germany), Gasparini (Italy), LVD (Belgium), and Bystronic (Switzerland) showcased the real-time following function of bending followers at the EuroBlech exhibition in Hannover, Germany. At the same time, AMADA (Japan) also launched its own bending follower devices between 1995 and 2000. With continuous technological upgrades, bending follower systems evolved from hydraulic control to servo control.

Industry Demand Background

Press brakes are essential equipment in sheet metal processing. As demand for bending efficiency continues to rise, challenges emerge in bending large and heavy sheets. Traditional manual-assisted bending and simple front support stands for press brakes can no longer meet the efficiency and accuracy requirements of large workpiece processing.

Manual operations for large sheet bending face several disadvantages:

1.Bending large sheets often requires 3–4 people, leading to high labor consumption and low accuracy.

2.Operators face high physical strain, reduced efficiency, and potential risks of work-related injuries.

3.Enterprises incur higher labor and management costs, making lean production difficult to achieve.

What Is a Bending Follower?

A bending follower is an auxiliary device for press brakes. Initially called Dynamic Front Support, it is now more commonly known as Bending Follower or Sheet Follower.

Its main function is to provide dynamic support and flipping of sheet materials during bending, reducing the operator’s workload and labor requirements, while simultaneously ensuring bending precision. By preventing sheet sagging or deformation caused by its own weight or bending motion, the follower tracks the sheet position in real time and automatically adjusts the height and position of the support. This ensures stable sheet support throughout the bending process, improving accuracy and efficiency while saving time, labor, and costs.

Types of Bending Followers

Bending followers are classified based on their control method and how they connect to the press brake. They can generally be divided into combined type bending followers and floor type bending followers.

Combined Type Bending Follower

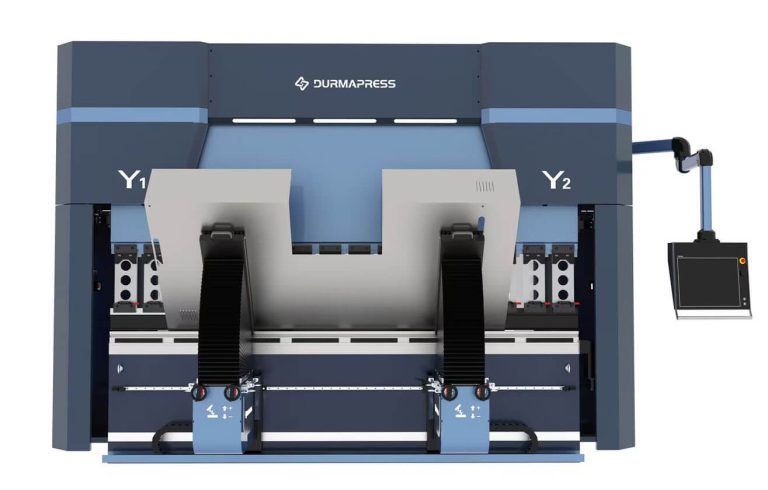

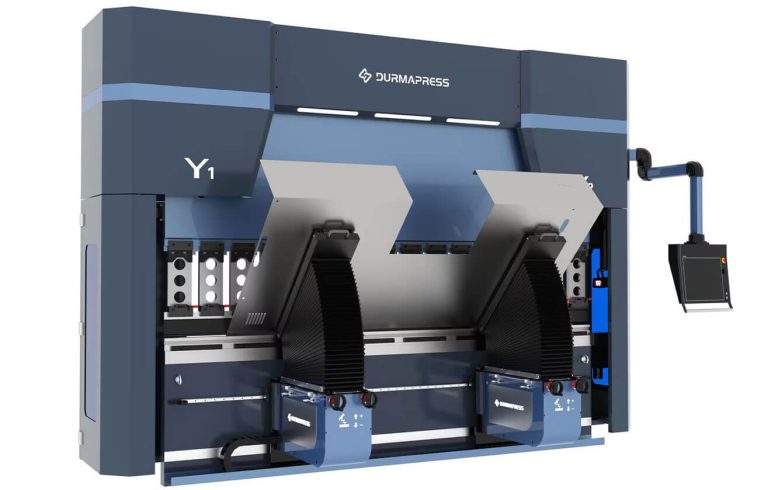

As the name suggests, the combined type bending follower is built directly into the press brake. This is the traditional European version of the bending follower. It is installed on the lower beam of the press brake via a mounting base, guide rail slider, and cam structure. It can slide horizontally along the Z-axis (the length direction of the press brake) and is directly controlled by the CNC system of the press brake.

During bending, the support platform can be adjusted vertically, horizontally (Z-axis), and laterally (X-axis) to support the workpiece while following the bending angle in real time.

Floor Type Bending Follower

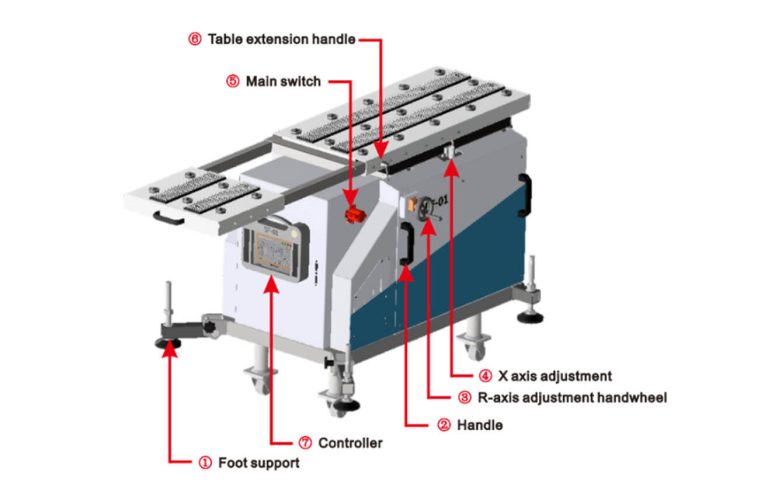

The floor type bending follower, also known as a bending follower cart, is essentially an evolution of the integrated version. It features an enlarged external frame and a redesigned base structure. Equipped with rollers, it can be moved into position and fixed securely on the ground with foot supports.

The robust base and foot structure ensure stability during bending, keeping the sheet material supported throughout the process. It is equipped with an independent programmable controller, making it compatible with various models of press brakes and offering strong versatility.

Main Structure of Bending Followers

Combined Type Bending Follower: consists of a base assembly, main frame, rotating unit, main support table, and X-axis & R-axis adjustment mechanisms.

Floor Type Bending Follower: consists of an external frame, rotating unit, main support table, electrical cabinet, controller, and X-axis & R-axis adjustment mechanisms. Among these, the external frame, rotating unit, and table belong to the mechanical components, while the electrical cabinet and controller form the electrical components.

Operating Modes of Bending Followers

Bending followers generally operate in three states:

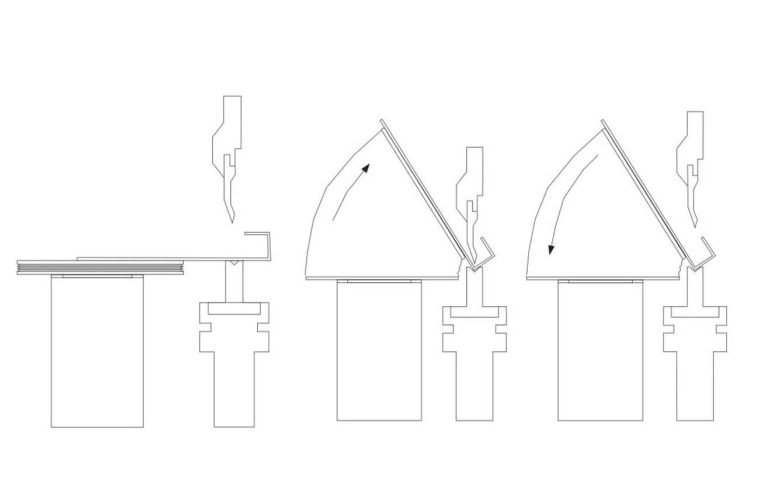

Zero Position State

When the follower function is not activated, or when the upper ram has not yet reached the clamping point, the follower remains at the zero position.

Following State

Once the follower function is activated and the ram descends past the clamping point, the follower enters the following state. It synchronizes with the ram’s movement speed during the bending process until the ram reaches the bottom dead center.

Return State

After the bending process finishes, the ram begins to return, and the follower also slowly returns to its zero position, completing the cycle.

For combined type bending followers, operation is controlled via the CNC system of the press brake (e.g., DELEM, ESA, Cybelec). Users need to enable the follower axis function, configure parameters, and link it to the bending program.

For floor type bending followers, operation is managed through an independent control panel. Users configure the required parameters, record values, set bending steps, and then enable the follower function for synchronized operation with the press brake.

Applications and Advantages of Bending Followers

Applications of Bending Followers

Bending followers play a significant role in helping enterprises reduce costs and improve efficiency. In recent years, they have been widely used in industries such as high- and low-voltage switchgear, elevators, aluminum curtain walls, construction machinery, household appliances, steel structures, shipbuilding, and defense.

Customers can choose an combined type bending follower when purchasing a new press brake from DURMAPRESS, or they can retrofit existing machines with a floor type bending follower, upgrading old equipment to extend its service life and maximize value.

Different models are available to meet varying customer needs based on press brake tonnage, length, and sheet size and weight:

Combined Type Bending Follower:

F1 model (lifting capacity 180 kg)

F1P model (lifting capacity 380 kg)

Floor Type Bending Follower:

BF-01 model (lifting capacity 180 kg)

BF-02 model (lifting capacity 380 kg)

BF-03 model (lifting capacity 130 kg, specialized for aluminum curtain walls)

BF-06 model (lifting capacity 120 kg)

BF-01-R75 model (lifting capacity 180 kg, specialized for flattening and bending)

Customers may use a single follower, dual synchronized followers, or even systems with six or more synchronized units for complex bending operations.

Key Advantages of Bending Followers

Suitable for large sheet bending, significantly reducing operator workload.

Fully synchronized with the press brake’s Y-axis through CNC communication.

Improves machining efficiency and ensures bending angle accuracy.

Automatically adjusts up/down, forward/backward movements based on die height and V-opening size.

Optional roller supports for easy sheet rolling and flipping.

Optional brush tables to prevent sheet scratches, slipping, or falling.

Optional automatic R-axis for flattening bends.

Expandable table design to handle different workpiece sizes.

Additional advantages of floor-mounted bending followers include:

Independent control system – no need to upgrade the original CNC of the press brake, compatible with any model.

Flexible and user-friendly – easy to install/uninstall, and can be shared across multiple press brakes.

Conclusion

With the rapid rise of Industry 4.0 and intelligent manufacturing, bending follower technology continues to evolve under the dual drivers of technological innovation and industry demand.

At DURMAPRESS, we remain dedicated to advancing press brake solutions, adhering to principles of specialization, precision, innovation, and efficiency. Through continuous R&D and application of bending follower technology, we empower sheet metal manufacturers to embrace new processes and meet emerging production requirements.

By partnering with leading press brake manufacturers and leveraging cutting-edge automation, we aim to drive the transformation of traditional sheet metal processing toward a future that is smarter, greener, more connected, and more energy-efficient.