What is hydraulic clamping?

Concept of hydraulic fixtures

Hydraulic fixture is a type of fixture that realizes automatic positioning, supporting and clamping of workpieces through hydraulic components instead of mechanical parts. Hydraulic fixture has the advantages of high clamping force, reliable clamping, smooth operation, easy to use, etc. It is widely used in CNC machine tools, machining centers, automated production lines and other scenarios.

There are many types of hydraulic fixtures, including hydraulic thimble type fixtures, hydraulic plate type fixtures, hydraulic rotary fixtures, hydraulic panel type fixtures and specially adapted hydraulic fixtures. Each type of fixture has its own specific application scenarios and advantages. For example, hydraulic thimble type clamping force is large, suitable for high-speed processing; hydraulic plate type clamp is suitable for processing flat plate, can ensure the flatness and accuracy of the workpiece; hydraulic rotary clamp can make the workpiece in different angles for processing, suitable for processing complex workpieces.

Choosing the Right Hydraulic Clamping

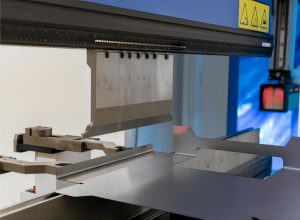

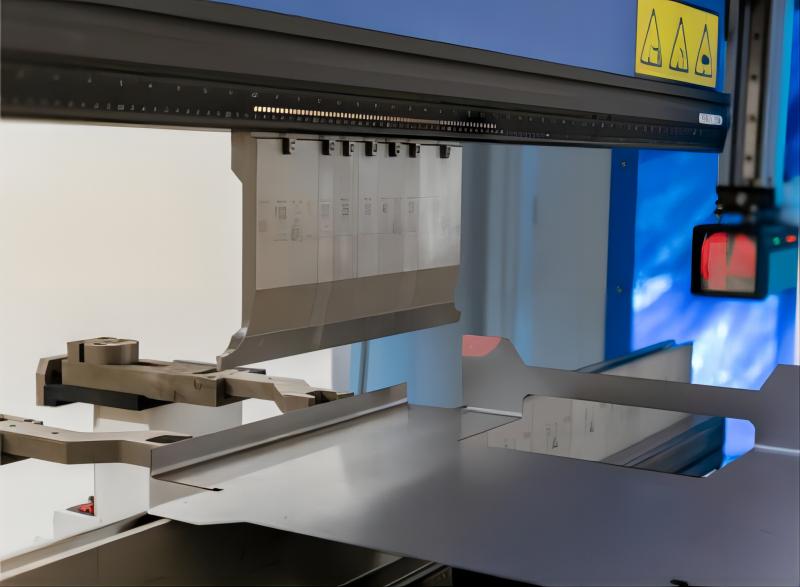

Choosing the right hydraulic clamping for a press brake is crucial as it ensures precise gripping, stabilizing the workpiece during the bending process, thus enhancing machining accuracy and consistency. By precisely controlling the clamping force and position, it effectively minimizes any movement or vibration of the workpiece during processing, thereby reducing machining errors and improving product quality and precision. Ultimately, this leads to increased productivity, helping businesses achieve higher levels of production and competitiveness.

Hydraulic Fixture System Basic Principles

The basic operating principle of a hydraulic fixture system involves using hydraulic pressure to clamp or release fixture components. Specifically, the hydraulic fixture system comprises a hydraulic cylinder and related control system. When hydraulic pressure is applied, the piston inside the hydraulic cylinder moves outward, pushing the fixture components to clamp the workpiece. Conversely, when hydraulic pressure is released, the fixture components loosen, releasing the workpiece.

In press brake applications, hydraulic fixture systems are commonly used for clamping and positioning metal workpieces to facilitate bending or folding operations. The applications of hydraulic fixture systems include:

- Workpiece Clamping: In a press brake, hydraulic fixture systems are used to clamp various shapes and sizes of metal workpieces, ensuring they remain stable during bending.

- Workpiece Positioning: Hydraulic fixture systems can also be used for positioning workpieces to ensure they are correctly aligned and positioned during braking, resulting in precise bending angles and dimensions.

- Improving Productivity: Hydraulic fixture systems enable quick clamping and releasing of workpieces, thereby enhancing the productivity of the press brake. They can facilitate automated operations, reduce manual intervention, and maintain consistent clamping force and precision in repetitive operations.

Key Factors in Selecting Hydraulic Fixtures

- Fixture Type and Specifications: For simple workpieces such as cylindrical or flat parts, commonly used fixtures include flat-jaw clamps, V-blocks, etc. However, for complex-shaped workpieces, custom-designed fixtures may be required to ensure stability and accuracy during processing. When selecting fixtures, the shape, size, and processing requirements of the workpiece must be fully considered to ensure the selected fixtures meet the processing needs.

- Clamping Force of Fixtures: Inadequate clamping force can result in workpiece displacement or vibration during processing, affecting machining accuracy and workpiece quality. Therefore, when selecting fixtures, it is essential to ensure they provide sufficient clamping force. This typically requires considering factors such as the material, structure, and clamping method of the fixtures.

- Accuracy and Stability of Fixtures: Positioning accuracy refers to the fixture's ability to position the workpiece relative to the machine tool coordinate system when fixing the workpiece. Repetitive positioning accuracy refers to the consistency of the workpiece position when multiple fixtures of the same workpiece are installed. To improve machining accuracy, fixtures with high positioning accuracy and good repetitive positioning accuracy must be selected. Consider the positioning accuracy and repetitive positioning accuracy of the fixtures to ensure machining accuracy.

- Durability and Maintenance of Fixtures: Durable fixtures can reduce replacement frequency, downtime, and maintenance costs.

Performance Evaluation of Hydraulic Fixture Systems

- Fixture Response Speed: Analyze the response speed of the fixture when starting and stopping to ensure machining efficiency. Response speed refers to the transition time for the fixture from a static state to starting work and from a working state to stopping, considering its driving method and control system.

- Fixture Reliability: Evaluate the stability and reliability of the fixture during long-term operation, considering factors such as its material, manufacturing process, and durability. High-quality materials and manufacturing processes can ensure the fixture has high strength and wear resistance, reducing failures due to fatigue or wear.

- Fixture Safety: Mainly reflected in its protective devices and ease of operation. For example, fixtures should be equipped with protective covers or guards to prevent splashing or ejection of workpieces or fixture components during processing, ensuring the safety of operators. Pay attention to the safety performance of the fixtures to ensure the safety of operators.

The basic principle of hydraulic fixture system

The basic working principle of hydraulic fixture system is to use hydraulic pressure to clamp or release the fixture components. Specifically, a hydraulic fixture system consists of a hydraulic cylinder and an associated control system. When pressure is applied by the hydraulic system, the piston inside the cylinder moves outward, pushing the fixture part to clamp the workpiece. Conversely, when the hydraulic system releases pressure, the fixture component loosens and releases the workpiece.

Fixture Classification

Classification based on the power source driving the fixture

- Manual Fixture: Fixtures operated manually by operators, typically used for simple workpiece clamping and positioning.

- Pneumatic Fixture: Fixture systems driven by air pressure, capable of quickly clamping and releasing workpieces, suitable for applications requiring rapid operation and significant clamping force.

- Hydraulic Fixture: Fixture systems driven by hydraulic systems, providing high clamping force and precision, suitable for processing applications requiring high clamping force and precision.

- Electric Fixture: Fixture systems driven by electric motors or electric hydraulic systems, capable of automated clamping and releasing of workpieces, suitable for automated production lines and mass production.

- Magnetic Fixture: Fixture systems using magnetic principles to hold workpieces, suitable for applications where no damage to the workpiece surface is desired.

- Vacuum Fixture: Fixture systems using vacuum suction cups or vacuum pumps to generate negative pressure for holding workpieces, suitable for flat workpieces or thin materials.

- Self-Locking Fixture: Fixture systems with self-locking functions, capable of maintaining clamping state without external power sources, suitable for applications requiring long-term clamping and high stability.

Analysis of WILA brand and their characteristics

This tool series, bearing the WILA brand, offers a variety of clamping options, with hydraulic clamping being a particularly favored choice. This system provides reliable clamping force, ensuring stability and precision during the machining process of tools and workpieces. The advantages of hydraulic clamping extend beyond its robust clamping force to include its ease of operation and reliability. By utilizing hydraulic clamping systems, you can effortlessly secure various types of tools and workpieces without concerns about insufficient or uneven clamping force. Furthermore, our hydraulic clamping systems come equipped with the Smart Tool Locator® (STL), an advanced feature enabling precise tool positioning and alignment, further enhancing machining efficiency and product quality.

Suggestions for selecting high-quality hydraulic clamping brands

- Look for brands known for their precision engineering and durability, such as Enerpac or Roemheld.

- Consider brands like Destaco or Hilma, which offer a wide range of hydraulic clamping solutions suitable for various applications.

- Explore options from reputable brands like Hydrotec or Pascal, known for their innovative features and reliability.

Case Analysis and Practical Application

Metalworking industry

In Durmapress, hydraulic clamps are frequently used to maintain the stability of workpieces during the bending process to ensure the accuracy of bending angles. In the use of the press brake, workers select appropriate hydraulic clamps as needed and install them on the bending machine. After placing the workpiece on the press brake, hydraulic clamps precisely grip the workpiece to ensure its stability during bending. Operating the hydraulic system according to preset parameters precisely controls the pressure and position of the clamps to ensure the accuracy and consistency of each bend. This precise clamping and control mechanism effectively prevents movement or vibration of the workpiece during bending, thereby ensuring the accuracy of the bending angles. By using hydraulic clamps, we are able to produce high-quality, precisely reliable metal parts that meet customer requirements, and help us continually improve product quality and production efficiency.

Conclusion

When selecting hydraulic clamps for a press brake, the primary objectives are to provide high-precision clamping, maintain stability, and enhance productivity. To achieve this, it's essential to consider machining requirements, compatibility of the clamps, quality, reliability, and cost factors. If you require hydraulic clamps, we recommend contacting Durmapress and discussing your specific needs. We will provide you with detailed assistance to ensure that the hydraulic clamps you choose meet your requirements perfectly. Different hydraulic clamps correspond to varying levels of productivity and production demands. Therefore, it's crucial to pay attention to the compatibility of the clamps with your workpieces and to assess the positioning and clamping capabilities of the hydraulic system. With the increasing importance of automation and intelligence in modern industrial development, it's essential for businesses to consider their own needs and maximize production efficiency accordingly.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.