About Us

Compare CNC and manual control in hydraulic shearing machines to understand their impact on accuracy, efficiency, operator dependency, and production cost in sheet metal fabrication.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

In sheet metal fabrication, machine structure and blade quality are critical, but the control system often determines long-term production stability, efficiency, and accuracy.

As manufacturing environments evolve toward higher precision and faster turnaround, many workshops face a practical question:

Should you choose CNC control or manual control in a hydraulic shearing machine?

This article compares CNC and manual control from a real production perspective, focusing on accuracy, repeatability, efficiency, cost, and operational impact.

Why the Control System Matters in Sheet Metal Production

A hydraulic shear may have a rigid frame and high-quality blades, yet still produce inconsistent results if cutting parameters are poorly controlled.

In modern fabrication, manufacturers must handle:

- Multiple material types

- Frequent thickness changes

- Batch production with tight tolerances

- Pressure to reduce scrap and rework

Under these conditions, the control system becomes just as important as the mechanical design.

What Is Manual Control in Hydraulic Shears?

Manual control systems rely on mechanical adjustments and operator input rather than programmed automation.

Typical characteristics include:

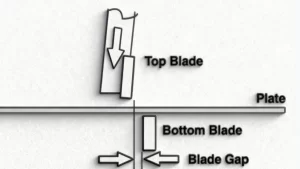

- Mechanical blade clearance adjustment

- Manual back gauge positioning

- Limited parameter memory

- Heavy reliance on operator experience

Manual hydraulic shears remain widely used due to their simplicity and lower initial cost, particularly in smaller workshops.

To understand how these adjustments affect cutting performance, it helps to review how hydraulic shearing machines work and how parameters influence cutting behavior.

What Is Manual Control in Hydraulic Shears?

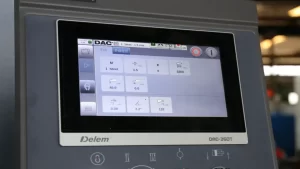

CNC (Computer Numerical Control) systems automate parameter calculation and machine adjustments through digital programming.

In CNC-controlled hydraulic shears, the system typically manages:

- Blade clearance

- Back gauge positioning

- Cutting stroke

- Cutting sequences

- Material thickness input

- Program storage

This transforms shearing from a manually tuned process into a repeatable and data-driven operation.

For example, one of the most critical automated functions is blade clearance adjustment, which directly affects edge quality and blade life.

Impact on Cutting Accuracy and Consistency

Manual Control

Accuracy depends heavily on:

- Operator skill

- Correct mechanical adjustments

- Consistency of parameter settings

Even with experienced operators, maintaining identical accuracy across long production runs can be challenging.

CNC Control

CNC systems improve:

- Positioning precision

- Parameter consistency

- Repeatability across batches

This is particularly valuable when cutting:

- Stainless steel

- Thick plates

- Precision components

For a deeper look at how automation improves precision, see our analysis of how CNC control improves accuracy in hydraulic shearing machines.

Impact on Production Efficiency

Production efficiency is influenced by:

- Setup time

- Adjustment frequency

- Job switching speed

- Error rates

Manual Control Limitations

Manual systems typically require:

- Physical blade clearance adjustments

- Repositioning back gauge

- Trial cuts for verification

This increases downtime during thickness or dimension changes.

CNC Control Advantages

CNC-controlled shears enable:

- Rapid parameter input

- Automatic adjustments

- Stored program recall

- Faster transitions between jobs

This significantly improves efficiency in multi-specification or batch production environments.

Cost Comparison: Short-Term vs Long-Term

Initial Investment

- Manual shear → Lower purchase cost

- CNC shear → Higher purchase cost

This is often the main hesitation point for buyers.

Long-Term Production Cost

However, total production cost includes more than machine price:

Total Cost = Machine Cost + Labor + Scrap + Downtime + Maintenance

CNC systems help reduce:

- Scrap caused by parameter errors

- Labor intensity

- Setup-related downtime

- Blade wear from incorrect clearance

Over time, CNC machines often deliver better cost efficiency, especially in medium-to-large-scale production.

Operator Dependency and Skill Requirements

Manual Control

Requires:

- Skilled operators

- Experience-based adjustments

- Continuous monitoring

Performance may vary between operators and shifts.

CNC Control

Reduces dependency on:

- Individual operator expertise

- Manual parameter tuning

While training is still necessary, CNC systems standardize production behavior.

When Manual Control Is Still Suitable

Manual hydraulic shears remain practical when:

- Production volume is low

- Material type is consistent

- Thickness changes are infrequent

- Budget constraints are strong

- Precision requirements are moderate

For small workshops or simple cutting tasks, manual control can be a cost-effective choice.

When CNC Control Becomes Necessary

CNC control becomes highly beneficial when:

- Handling multiple materials

- Frequent thickness variation

- Batch production with tight tolerances

- High scrap reduction targets

- Labor optimization goals

In these environments, a guillotine hydraulic shearing machine with CNC control typically provides superior stability, accuracy, and efficiency.

Conclusion

Choosing between CNC and manual control in a hydraulic shear is not simply a matter of automation preference—it is a production strategy decision.

Manual control offers simplicity and lower initial cost

CNC control delivers superior accuracy, repeatability, efficiency, and long-term cost benefits

For workshops aiming at scalable, high-precision, or multi-material production, CNC-controlled hydraulic shearing machines represent a practical and future-oriented investment.

FAQ: CNC vs Manual Control in Hydraulic Shears

Is CNC always more accurate than manual control?

CNC improves accuracy through consistent parameter control, but machine rigidity and blade condition remain important.

Is CNC worth the higher investment?

For high-volume or precision production, CNC often reduces scrap, downtime, and labor cost enough to justify the investment.

Can manual shears achieve good cutting quality?

Yes, especially with skilled operators and stable production conditions.

Does CNC automatically adjust blade clearance?

Most modern CNC hydraulic shears support automatic blade clearance calculation and adjustment.