Introduction to Metal Fabrication Machines & Equipment

Importance of Metal Fabrication in Industry

Metal fabrication is an important part of industrial production and is used in a variety of fields and plays an integral role in all of them. Therefore, choosing the right metal fabrication equipment is crucial because it directly affects productivity, product quality, and the competitiveness of an organization.

Purpose of choosing the right machine

The purpose of choosing the right metalworking equipment is to improve productivity and product quality, reduce production costs, adapt to changes in market demand, and realize the sustainable development of the enterprise. With suitable equipment, we can speed up the processing speed, ensure the consistency of product size and quality, reduce the production cycle and defective rate, so as to increase the output and production capacity, and to meet the needs of different customers and improve the competitiveness of the market. In addition, suitable equipment can also reduce manual labor and energy consumption, promote resource utilization efficiency, reduce environmental pollution, and achieve the goal of sustainable development of enterprises.

Key Metal Processing Equipment Types

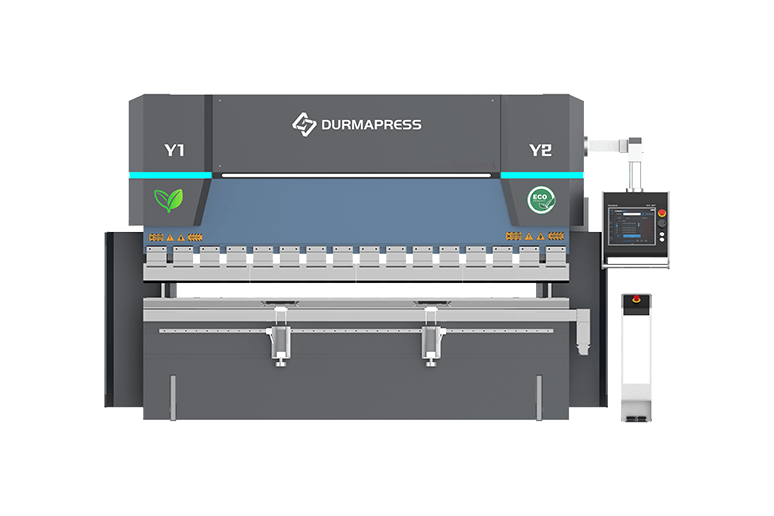

Press Brakes are used to bend sheet metal into a predetermined angle and shape by applying mechanical pressure.Press Brakes are capable of high-precision bending to ensure consistent product size and shape, and are suitable for a wide range of metal materials, such as steel, stainless steel, and aluminum, which are widely used in automotive, aerospace, construction, and home appliance industries. Modern Press Brakes are usually equipped with CNC (numerical control) systems, which can be programmed and controlled to adapt to different production needs. Some advanced Press Brakes also have a high degree of automation, which can significantly improve production efficiency and operational safety.

Laser Cutting Machine utilizes a high-energy laser beam to cut metal sheets, which has the advantages of fast cutting speed, high precision and narrow cutting slit. Laser Cutting Machine is widely used in metal processing of complex shapes, suitable for stainless steel, carbon steel, aluminum alloy and other materials, especially in automotive manufacturing, aerospace, electronic equipment and decorative industries, especially in the performance of the Laser Cutting Machine is usually equipped with advanced numerical control system, which can realize automation of the cutting, improve productivity and reduce human error, and at the same time reduce the waste of materials and production costs. and production costs.

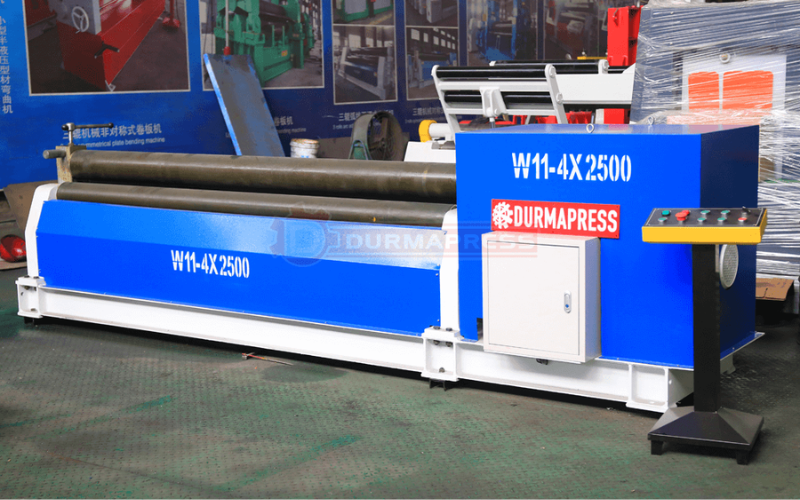

Rolling Machines are used to form and control the thickness of sheet metal by applying pressure to a rotating roller, which causes plastic deformation to achieve the desired thickness and shape.Rolling Machines are widely used for forming and controlling the thickness of steel, aluminum, stainless steel and other materials, and are commonly used in the steel, automotive, shipbuilding and construction industries. Rolling machines are characterized by high efficiency, continuous processing, and the ability to handle large sizes and batches of sheet metal. Modern rolling machines are often equipped with automated control systems to improve productivity and product quality.

Shearing Machines cut sheet metal by the relative motion of the upper and lower blades, and are suitable for cutting large pieces of sheet metal to the required size.The main advantage of the Shearing Machine is its efficient and precise cutting ability, which makes it suitable for a wide range of thicknesses of sheet metal, such as steel, aluminum, stainless steel, etc. Shearing Machines are used in the Widely used in the metalworking, manufacturing and construction industries, modern Shearing Machines are often equipped with CNC controls that enable them to make precise cuts according to pre-set programs, improving productivity and cutting quality.

Key Considerations for Selecting a Shearing Machine

Material Compatibility

Different equipment is suitable for different types of metal processing, and it is important to choose equipment that is compatible enough to handle the material you need, based on your needs. For example, some equipment may be better suited to process steel, while others are better suited to process materials such as aluminum or stainless steel. It is important to ensure that the equipment you choose is able to effectively process the type and thickness of material required.

Machine performance

The performance of the equipment has a direct impact on productivity and product quality. Performance indicators of interest include processing speed, accuracy, stability, and equipment durability and reliability. Good equipment should be able to provide high-speed, high-precision machining and be able to operate consistently with minimal breakdowns and downtime.

Technology and Innovation

Technology and innovation are critical to the selection of metalworking equipment. Advanced technology and innovative design can increase productivity, reduce energy consumption, and lead to higher machining accuracy and quality. Therefore, when selecting equipment, consider whether it has the latest technology and innovative features.

Cost and budget

The cost of the equipment is one of the most important factors that must be considered in the selection process. In addition to the purchase cost of the equipment itself, the operating costs, maintenance costs and potential upgrade and replacement costs of the equipment need to be taken into account. It is important to ensure that the performance and functionality of the equipment selected is in line with the budget and will provide a good return on investment.

Manufacturer and supplier considerations

The manufacturer and supplier of the equipment is also an important factor to consider in the selection process. Choosing a reputable manufacturer and supplier with extensive experience and good after-sales service will ensure the quality and performance of the equipment, as well as the ability to provide timely technical support and maintenance services. durmapress has been focusing on customer service, technical support and communication since its inception, and has gained a good reputation for this.

Specific selection criteria for different equipment

Press Brake

Tonnage and bending capacity: Select the appropriate tonnage for the type and thickness of the metal material to be bent to ensure that the machine is able to provide sufficient pressure to complete the required bending task.

Table Length: The length of the table should meet the dimensional requirements of the part to ensure that it can accommodate and handle the required sheet metal.

CNC: Modern press brakes are usually equipped with a CNC system, which should be selected for its programming capabilities, operator interface and degree of automation to improve productivity and machining accuracy.

Precision and Repeatability: The precision and repeatability of the equipment is an important indicator to ensure the quality of the product, choose the press brake machine with high precision control and stability performance.

After-sales service and maintenance: the maintenance of the press brake machine is crucial to its long-term stable operation, choose a manufacturer with good after-sales service and maintenance support.

Laser Cutting Machine

Laser Power: Laser power determines the thickness and speed of the cut. Select the power that is appropriate for the material and depth of cut required to ensure efficient processing.

Cutting accuracy: Cutting accuracy is the key to ensure the quality of processing, choose the equipment with high precision cutting ability.

Cutting speed: High-speed cutting can improve productivity, choose the laser cutting machine with fast and stable cutting speed.

Applicable materials: Consider the applicability of the equipment to different materials to ensure that it can effectively handle steel, stainless steel, aluminum alloys and other metals that need to be processed.

Automation and software support: Modern laser cutting machines are usually equipped with automated control systems and intelligent software, so choose equipment with advanced control features and user-friendly interfaces.

Maintenance and Operating Costs: Consider the daily maintenance needs and operating costs of your machine, and choose a laser cutting machine that is easy to maintain and has low operating costs.

Rolling Machine

Roller Configuration: Select the appropriate roller configuration according to the processed material and product requirements, including the number of rollers, material and size to meet the molding needs.

Capacity: Consider the machine's capacity, including the maximum plate thickness and width it can handle, to ensure the machine can meet production requirements.

Drive system: The drive system of a rolling machine affects its performance and efficiency, so choose an efficient and stable drive system to ensure continuous production.

Automation: Modern rolling machines are often equipped with automated control systems, so choose a machine with intelligent controls and easy operation to increase productivity.

Durability and Maintenance: Rolling machines need to run steadily for long periods of time, so choose equipment with high durability and easy maintenance to minimize downtime and maintenance costs.

Shearing Machine

Shearing capacity: According to the thickness and material of the metal sheet to be sheared, select the appropriate shearing capacity to ensure that the equipment can successfully complete the shearing task.

Shear precision: high precision shear to ensure product quality, choose the equipment with high precision shear capacity.

Cutting speed: cutting speed affects production efficiency, choose the cutting speed and stability of the shearer.

Blade material and life: consider the blade material and service life, choose high durability, easy to replace the blade, in order to extend the service life of the equipment.

Control system: modern shears are usually equipped with CNC systems, choose equipment with intelligent control and easy operation to improve the precision and efficiency of cutting.

Safety and Maintenance: Shearing machine operation needs to ensure safety, choose the equipment with safety guards and easy maintenance to ensure the safety of the operator and the long-term stable operation of the equipment.

and Safety Considerations

Compliance with safety standards

When selecting metalworking equipment, ensuring that it complies with local and international safety standards is a primary consideration. Compliance with safety standards not only ensures operator safety, but also enhances a company's credibility and compliance. For example, equipment should have safety devices such as emergency stop buttons and overload protection, and it should be designed and manufactured to meet international standards such as ISO and CE. These measures can effectively prevent accidents and ensure that the production process runs safely and smoothly.

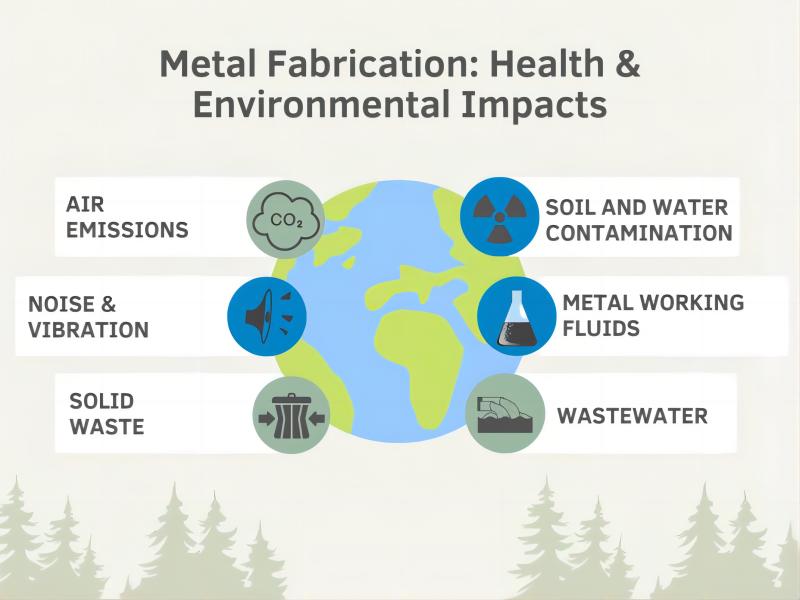

Emission control and environmental impact

Metal processing equipment will produce emissions such as waste gas, waste liquid and noise during operation, and these emissions will have a certain impact on the environment. Therefore, it is crucial to select equipment with good emission control capabilities. For example, laser cutting machines should be equipped with efficient exhaust gas purification systems, and rolling and shearing machines should adopt low-noise designs and lubrication systems to reduce environmental pollution. In addition, equipment should adopt energy-saving technologies wherever possible to reduce energy consumption and carbon emissions, promoting green production and sustainable development of the enterprise.

Ergonomics and operator safety features

Ergonomic design has a direct impact on operator health and efficiency. The control panel and operator interface of the equipment should conform to ergonomic design principles, be easy and comfortable to operate, and reduce operator fatigue. For example, the equipment should have an adjustable table height and display angle to ensure that the operator can operate in the most comfortable position. In addition, the equipment should be equipped with the necessary protective devices, such as goggles, protective gloves and shields, to prevent possible injuries during operation.

Future Planning and Expandability

Upgrade and Expandability

As market demand changes and technology advances, companies need equipment with good upgradability and expandability. For example, CNC press brake machines and laser cutting machines should have a modular design to facilitate future functional upgrades and expansion. In this way, enterprises can adjust the equipment configuration flexibly according to the actual production demand, improve production flexibility and competitiveness.

Adapt to technological advances

When selecting equipment, should consider whether it has the potential to adapt to future technological development. For example, the equipment should have the ability to be compatible with smart manufacturing systems and be able to seamlessly connect with emerging technologies such as the Internet of Things (IoT) and artificial intelligence (AI). In this way, companies can realize intelligent production and management, improve productivity and product quality, driven by future technological advances.

Long-term viability and flexibility

The long-term viability and flexibility of the equipment is crucial to the growth of the business. When selecting equipment, its suitability for different production environments and market conditions should be considered. For example, the equipment should be able to handle a wide range of materials and diverse products and adjust quickly when the production process changes. In addition, the equipment should have a long service life and low maintenance costs to minimize the long-term investment risk of the enterprise.

Conclusion

In summary, environmental and safety factors should be taken into account when selecting metalworking equipment to ensure that the equipment meets safety standards, has good emission control and environmental impact, as well as ergonomic design and operator safety features. Also, the future planning and scalability of the equipment are key considerations, including its ability to be upgraded and expanded, its potential to adapt to technological advances, as well as its long-term viability and flexibility. The final recommendation is that companies should regularly evaluate and upgrade their equipment to keep pace with market and technological developments, to ensure continuous improvement in productivity and product quality, and to achieve their sustainability goals. Regular equipment evaluation and upgrading not only identifies and solves potential problems, but also helps companies stay ahead of the curve in a competitive marketplace.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.