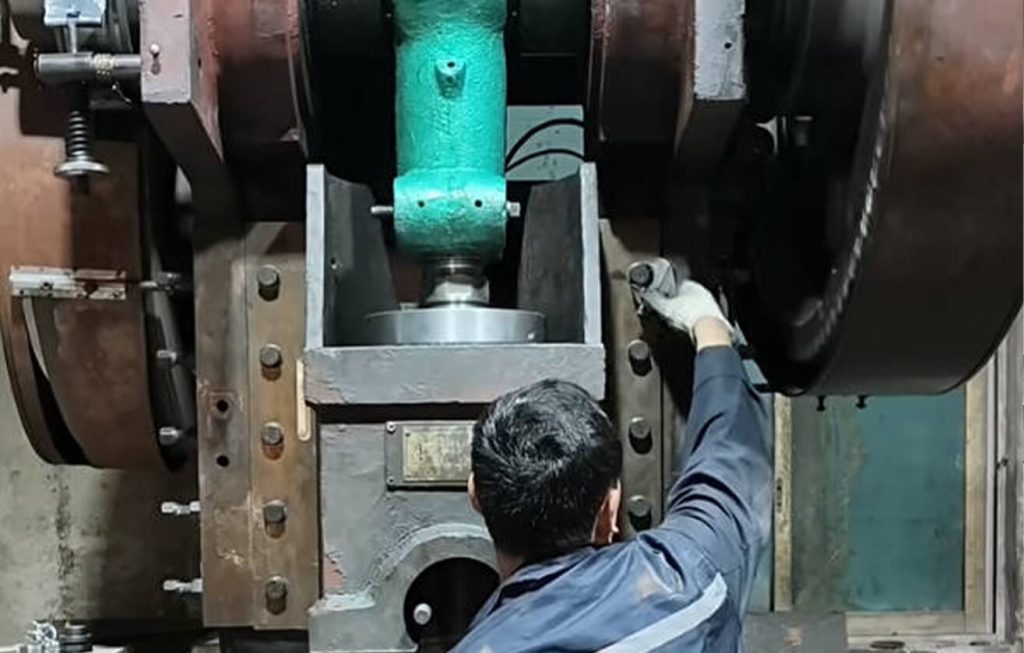

Lao Zhang's right hand will always remain on that familiar punch press.

At 3 o'clock that afternoon, he was operating the 250-ton punching machine as usual. The machine seemed to have a bit of a temper, and occasionally made a short abnormal noise when starting, but he thought, "I'll deal with it after I finish this batch of goods." Just as he reached out to adjust a slightly offset workpiece, the punch suddenly fell without any warning! The piercing alarm sounded and the pain came at the same time... Subsequent investigations found that an over-worn clutch key broke, causing the slider to fall unexpectedly, and the photoelectric device that was supposed to play a protective role failed due to oil stains.Such a tragedy could have been avoided. In the stamping industry, efficiency and risk coexist. High-speed moving metal, huge tonnage, instant impact force, any hidden danger in the equipment may turn into an accident that swallows limbs or even lives.

Why is daily inspection the "life-saving talisman" for stamping workers?

1.Take precautions before they happen:

Most serious accidents (such as continuous punching, accidental slide drop, mold cracking and flying out) are caused by the accumulation of small problems. Spot inspection can detect hidden dangers such as wear, looseness, leakage, and failure at an early stage.

2.Forced "pause" and observation:

In fast-paced production, spot inspections provide mandatory pause time, allowing operators to calmly check the status of equipment rather than operating it mindlessly.

3.Familiar with the "comrades" status:

Only by “taking the pulse” yourself every day can you fully understand the “health” of your equipment and perceive abnormal changes in the first place.

4.Implement safety responsibilities:

Inspection records are an important basis for clarifying responsibilities and tracing problems, and are a reflection of one's responsibility to oneself, colleagues, and family.

Remember: if you spend one extra minute on inspection, accidents may be avoided for your whole life.

Illustrated Guide to the Eight Core Systems of Daily Inspection of Stamping Equipment

(The following points must be performed after the equipment is powered off and the energy is fully released (such as flywheel stopping, air pressure/hydraulic pressure unloading)!)

System 1: Power and transmission system - the "heart" and "bones" of equipment operation

1.Motor and flywheel:

Check points: Are the motor base bolts, fan cover, and junction box tight? Is there any abnormal heating, vibration, or abnormal noise (such as buzzing or scraping)? Is the flywheel guard intact and securely fixed? Is there any obvious swing when the flywheel rotates?

Hazard illustration: [Diagram: flywheel guard is missing or damaged, fingers may be caught in it; motor junction box cover is loose, wires are exposed].

Common hidden dangers: abnormal noise from the motor (bearing damage), flywheel swing (spindle bending or bearing wear), and protective cover failure.

2.Belt/Gear Drive:

Check points: Is the belt tension appropriate (press with thumb, the sag is about 10-15mm)? Is there any serious wear, cracks, or oil stains? Is the gearbox oil level within the mark? Is there any oil leakage? Is there any abnormal noise when the gears mesh?

Hidden danger illustration: [Diagram: The belt is severely worn and cracked; the gearbox oil window shows that the oil level is too low; there are oil stains on the ground].

Common hidden dangers: belt slippage and breakage; gear wear and tooth breakage due to lack of oil; oil seal failure and oil leakage.

System 2: Clutch and brake - the life switch that controls "movement" and "stopping"

1.Clutch (pneumatic/mechanical):

Inspection points: Pneumatic clutch: Check whether the air pipe is aged, broken, or leaking? Is the pressure gauge at the set value (usually 0.4-0.6MPa)? Is the exhaust unobstructed? Mechanical clutch: Check the wear of the friction plate (visual inspection or thickness measurement), and whether the key and keyway are loose or worn?

Common hidden dangers: Insufficient air pressure leads to poor engagement or incomplete separation (easy to cause continuous impact); excessive wear of the friction plate leads to insufficient torque transmission or slipping; loose/broken keys lead to loss of control.

2.Brakes (usually pneumatic or mechanical):

Check points: Is the brake pad/belt worn? Is the brake spring broken or fatigued? Is the brake wheel surface clean and oil-free? Check the pneumatic brake with the clutch air circuit. Focus on testing the braking angle! (According to the regulations, such as jog/single stroke test to see if the brake is sensitive and whether the slider can stop within the specified angle/distance).

Hidden danger illustration: [Diagram: the brake friction pad is soaked with oil; the brake spring is obviously deformed or broken].

Common hidden dangers: insufficient braking force due to oil on the friction plate or excessive wear; spring failure; oil on the brake wheel causing slippage. Brake failure is the main reason for the slider to fall unexpectedly!

System 3: Sliders and guide rails - the cornerstone of precise operation

1.Check points:

Is the lubricating oil on the guide rail surface sufficient and clean? (Observe the oil film or oil mark)

Is there any serious scratch, roughness, wear and depression on the guide rail surface?

Is the gap between the slider and the guide rail uniform? Is there any abnormal shaking? (You can use a feeler gauge to roughly measure at a specific point, or manually turn the wheel to feel the change in resistance)

Is the air pressure of the balance cylinder (if any) normal? Is there any leakage in the pipeline?

2.Hidden danger diagram:

[Diagram: the guide rail surface is dry and oil-free or dirty and black with oil; there are deep groove scratches on the guide rail surface; the slider shakes noticeably left and right when moving].

3.Common hidden dangers:

Lack of oil leads to dry friction, heat, accelerated wear and even "seizing"; damage to the guide rail leads to unstable operation, reduced accuracy and abnormal noise; excessive clearance causes vibration and noise..

System 4: Operation and control system - the "brain" of equipment operation

1.Master button station (two-hand button):

Check points: Are the button labels clear? Is the action flexible and without stagnation? Is the distance between the two-hand buttons sufficient (usually ≥250mm)? Is there a crisp "click" feedback sound when pressing? Is the emergency stop button (mushroom head) eye-catching, prominent, easy to press, and self-locking? It needs to be manually rotated out to unlock after resetting.

2.Hidden danger diagram:

[Diagram: the emergency stop button is covered with paint or damaged; one of the two-hand buttons is stuck by a foreign object and cannot pop up].

Common hidden dangers: Button stuck and ineffective; emergency stop button ineffective or difficult to reach; two-hand buttons with insufficient spacing or have been modified..

3.Foot switch (if used):

Check points: Is the protective cover intact? Is the switch flexible? Is there a risk of accidental stepping? Only use it in specific working conditions (such as debugging, small parts) and after approval. When using it, both hands must be away from the danger zone!

4.Travel switch/position sensor:

Check points: Is the installation firm? Is there any oil stain or iron filings on the sensing surface? Is the trigger rod/plate deformed? Test its function (e.g., observe the upper and lower dead point signals by jogging to see if they are accurate).

5.Electrical cabinet (external observation):

Check points: Is the cabinet door closed? Is the indicator light normal? Is there any abnormal burning smell? Is the cable entry seal intact?

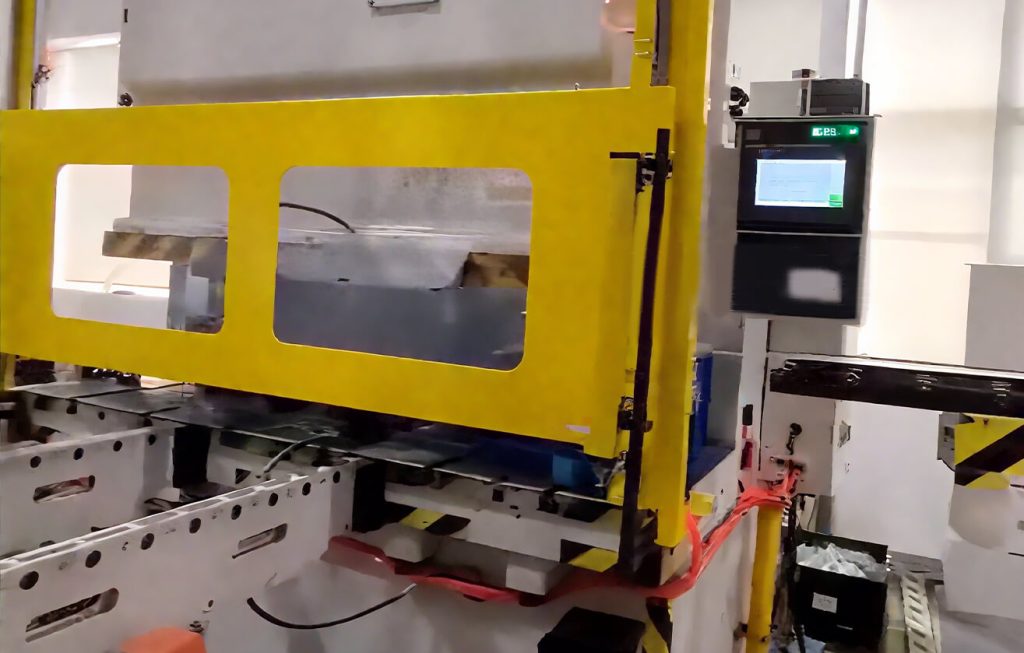

System 5: Safety protection device - the "golden bell" that directly protects the body

1.Fixed guards/fences:

Check points: Are all hazardous areas securely covered (e.g., transmission parts, periphery of mold area)? Are mesh/gap dimensions in compliance with safety standards (to prevent fingers and arms from entering)? Is the door/cover interlock effective (power off and shutdown when opened)? Test the interlock function!

2.Active protective devices (such as photoelectric protection, two-hand control):

Inspection points: Are the mirrors of the transmitter and receiver clean and free of dirt, oil stains, and obstructions? Is the installation firm and the beam accurate (observe the status indicator, usually green is normal)? Functional test: When the slider is moving downward (inching mode), if you block the light beam with your hand or a test rod, the slider must stop immediately! The protection height and range must cover the dangerous opening area. Does the response time meet the requirements (≤20ms)?

Photoelectric protection device (safety light curtain/grating):

Two-hand button device: Inspection points: Same as the main control button station. Function test: The slider will move only when both hands press the buttons at the same time; pressing one hand or one button will be invalid; releasing any button will cause the slider to stop immediately (within the feasible travel).

3.Emergency stop device

Check points: In addition to the emergency stop at the main button station, are additional emergency stop buttons set around the equipment (especially in places that are easily accessible to the operator)? Test the functions of all emergency stop buttons: After pressing, the main motor, clutch air source, etc. should be cut off immediately, and all moving parts should stop quickly (brake action).

4.Mold area safety bolts/safety pads:

Inspection points: Before entering the mold area for maintenance, debugging, and waste removal, you must confirm that: the equipment has been powered off and the energy has been released (flywheel stopped, air pressure/hydraulic pressure unloading)! You must use: Safety bolts or safety pads that meet the requirements (sufficient strength and size) are correctly placed between the slider and the workbench to prevent the slider from falling accidentally! Check whether the safety bolts are deformed or cracked.

System 6: Pneumatic and hydraulic systems - providing the "blood" of power

1.Pneumatic system:

Inspection points: Is the accumulated water in the air filter discharged in time? Is the oil level of the oil mist collector sufficient (1/2~2/3), and is the oil dripping speed appropriate? Is the pressure gauge normal and stable? Is there any obvious leakage ("hissing") at the cylinder, valve, or joint? Is the air pipe aging, cracked, or worn?

2.Hydraulic system (hydraulic press or hydraulic overload protection):

Inspection points: Is the oil level in the tank within the marked range? Is the hydraulic oil emulsified (white) or seriously contaminated? Is there any abnormal noise in the system (such as the scream of the pump)? Is there any oil leakage in the hydraulic pipeline, joints, and cylinder seals? Is the pressure gauge indication normal?

Common hidden dangers: Air leakage leading to insufficient pressure and slow movement; poor lubrication and wear of pneumatic components; hydraulic oil contamination leading to valve core sticking and system failure; low oil level leading to pump suction and damage; oil leakage polluting the environment and causing slips.

System 7: Molds and fixtures - the "weapon" of direct contact

1.Check points:

Is the mold installed firmly? Are the pressure plate, bolts, and washers tight and not loose? Are the positioning pins intact?

Is the mold edge sharp? Are there any chipping or cracks (especially small cracks)?

Are the moving parts such as springs, ejectors, and wedges flexible, without jamming or breakage?

Is the waste discharge smooth? Is there a risk of blockage?

Do the fixtures (suction cups, manipulators, etc.) work reliably? Are they loose or damaged?

2.Hidden danger diagram:

The bolts of the mold plate are loose; there is a small crack on the cutting edge; the waste hole of the lower mold is blocked by iron filings.

3.Common hidden dangers:

The loosening and displacement of the mold may cause the equipment to be crushed or the workpiece to fly out; the breaking of the cutting edge may cause fragments to fly out and injure people; the blockage of waste materials may cause the material to accumulate too high, affecting closing or ejection; the broken spring may cause the ejection to fail or the parts to be ejected.

System 8: Working environment and auxiliary facilities - safe "soil"

The loosening and displacement of the mold may cause the equipment to be crushed or the workpiece to fly out; the breaking of the cutting edge may cause fragments to fly out and injure people; the blockage of waste materials may cause the material to accumulate too high, affecting closing or ejection; the broken spring may cause the ejection to fail or the parts to be ejected.

1.Check points:

Is the floor of the work area clean, dry, free of oil and debris (especially iron filings, workpieces, tools)? Prevent slips and trips.

Is the lighting adequate? No glare, no dead angles?

Are the materials (sheet metal, workpieces, molds) neatly and firmly placed? At a reasonable height? Is the passage unobstructed?

Is the fire-fighting equipment (fire extinguisher) in the designated location and in good condition (pressure gauge pointer in the green zone)?

Is the equipment grounding wire firmly connected?

Inspection is not just about “ticking a box”, it is only effective if done this way!

1.Combination of “observation, listening, questioning and palpation”:

Look: Observe carefully (oil level, leakage, wear, deformation, looseness, cleanliness, indicator light).

Smell: Pay attention to abnormal smells (burnt smell, strong oil smell).

Ask: Listen for abnormal sounds (abnormal noise, air leakage, abnormal vibration).

Touch: Touch and feel appropriately (temperature, vibration, looseness - under the premise of safety!).

2.Follow standard procedures:

According to the equipment inspection form (see the example in the appendix), check each item without missing any item. The inspection form should be posted next to the equipment or kept by the team leader.

3.The “three no’s” principle when discovering problems:

No concealment, no delay, no compromise!Report to the team leader or maintenance personnel immediately and clearly describe the problem phenomenon and location. You have the right to refuse to operate before the hidden danger is eliminated!

4.Keep detailed records

Record the inspection results truthfully on the inspection form (√ for normal, × for abnormal and describe), and sign to confirm. Records are the basis for tracing and improvement.

5.Must-check shift handover:

Record the inspection results truthfully on the inspection form (√ for normal, × for abnormal and describe), and sign to confirm. Records are the basis for tracing and improvement.

Lessons learned from blood: The cost of neglecting inspections

Case 1: An operator in a factory did not notice that the brake pad was severely worn and stained with oil. After a stroke, the brake failed, and the slider slowly slid down, crushing his arm that was picking up the part.

Case 2: The photoelectric protector mirror was full of oil and failed without being discovered. The operator reached into the mold area to adjust the equipment before it completely stopped, triggering continuous punching, causing his palm to be crushed.

Case 3: The mold pressure plate bolts were loose and not tightened. During the stamping process, the mold shifted, and the workpiece flew out at high speed with fragments, hitting the head of the worker at the adjacent station and causing serious injuries.

These are not just stories, but tragedies that may happen every day in workshops around the world! Every illegal operation, every fluke, and every blind eye to hidden dangers are paving the way for accidents.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.