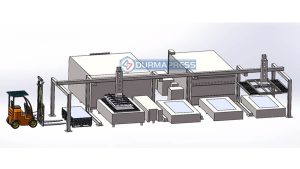

Control Cabinet Cleaning for a 3000W Fiber Laser Cutting Machine

- Use compressed air to remove dust from the circuit board inside the electrical cabinet.

- Verify and, if necessary, correct the CNC/Servo/Devicenet settings.

- Inspect and adjust the settings for each gas in Gascon.

- Check and calibrate the analog voltage adjustments for each servo axis.

- Clean the air conditioner's inlet and outlet filter screens with compressed air.

- Ensure the temperature inside the electrical cabinet is normal and that the air conditioning is functioning correctly.

- Confirm that the electrical control cabinet door is securely closed.

Dust Collector Cleaning for a 3000W Fiber Laser Cutting Machine

- Inspect the dust collector's hopper and clean it if the dust level exceeds 3/4 of its capacity.

- Check the pressure difference between the inlet and outlet of the filter element and replace it if necessary.

- Ensure the compressed air pressure at the dust collector's entrance is normal and clean the oil filter.

- Inspect the dust collector's seal for integrity and replace it if needed.

- Verify that the air duct is tightly sealed.

Water Cooler Cleaning for a 3000W Fiber Laser Cutting Machine

- Use compressed air to clean dust from the surface of the radiator, inside the water cooler, and on the fan weekly.

- Inspect for any water leakage inside the water cooler.

- Check the water level in the water cooler and add softened water if necessary.

- Regularly clean the filter element in the waterway.

Regular maintenance of the control cabinet, dust collector, and water cooler for a 3000W fiber laser cutting machine is essential to ensure optimal performance and longevity. By following these cleaning and inspection guidelines, you can prevent equipment failures, maintain operational efficiency, and reduce downtime.

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.