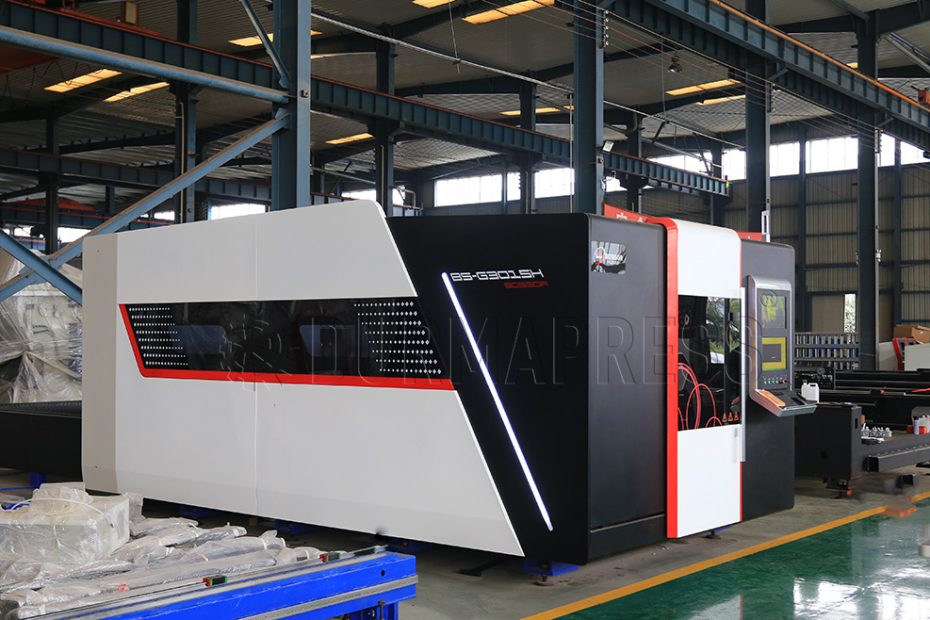

When we encounter some abnormal situations in the process of using optical fiber laser cutting machine at ordinary times, we must not be able to ignore,

I hope we can realize the importance of this point. In particular, when the servo motor abnormal phenomenon occurs

in the operation of the fiber laser cutting machine, special attention should be paid to it. The following is the reason analysis:

Many customers in the purchase of the company's production of fiber laser cutting machine,

Because altitude has adverse effects on motor temperature rise, motor corona (high voltage motor) and dc motor reversing. Therefore, we should pay attention to the following two aspects:

1. Corona prevention measures should be taken when the high-voltage motor is used at the plateau;

2. The altitude is unfavorable to the commutation of dc motor, so attention should be paid to the selection of carbon brush material.

Therefore, in the plateau area, we generally do not choose the ordinary motor, but the plateau special motor.

Second, in the cold environment why can not arbitrarily start the motor.

Because the motor is too long in low temperature environment, the following problems will occur:

1, motor insulation cracking;

2. Bearing grease freezing;

3, wire joint solder powder.

Therefore, the motor should be heated and preserved in a cold environment, and the windings and bearings should be checked before operation.

In short, no matter what kind of failure you encounter in the process of using fiber laser cutting machine, you must not be able to ignore it.