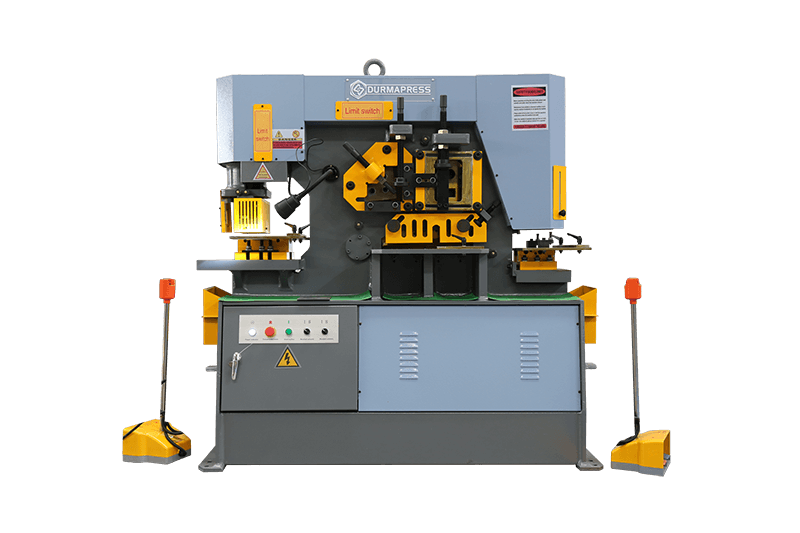

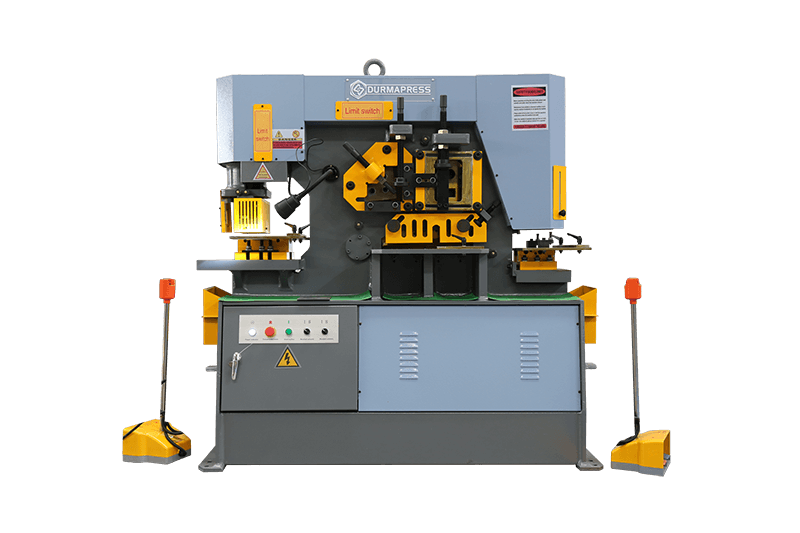

Hydraulic Ironworker

DURMAPRESS Hydraulic Ironworker adopts hydraulic transmission. It is the latest product of the domestic multi-functional combined punching and shearing machine. It can cut, punch, and die-cut flat steel, square steel, round steel, angle steel, channel steel, and I-beam.

Trusted by 5000+ manufacturers worldwide

Product Overview

Engineered for precision, efficiency, and reliability in modern manufacturing environments

High-Force Hydraulic Processing Technology

The DURMAPRESS Hydraulic Ironworker series provides reliable, high-force punching and shearing solutions for demanding metal fabrication workshops.

Advanced Technical Features

- Capable of cutting, punching, and die-cutting various steel shapes.

- Equipped with a shear stop device for added safety and precision.

- Utilizes hydraulic transmission for efficient operation.

- Combines multiple functions such as metal shearing, punching, plate shearing, and bending.

- Easy to operate, requiring minimal training.

- Efficient energy usage, reducing operating costs.

- Requires minimal maintenance, lowering overall maintenance expenses.

Ideal Applications

- Structural steel processing

- Plate and bracket punching

- Flat material shearing

- Frame and joint notching

- General fabrication workshop use

durmapress

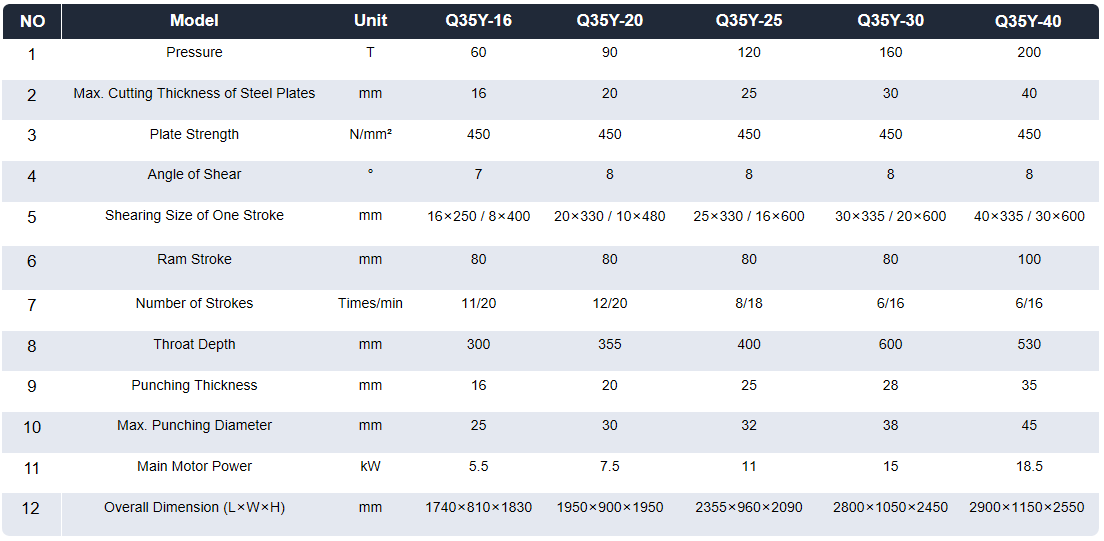

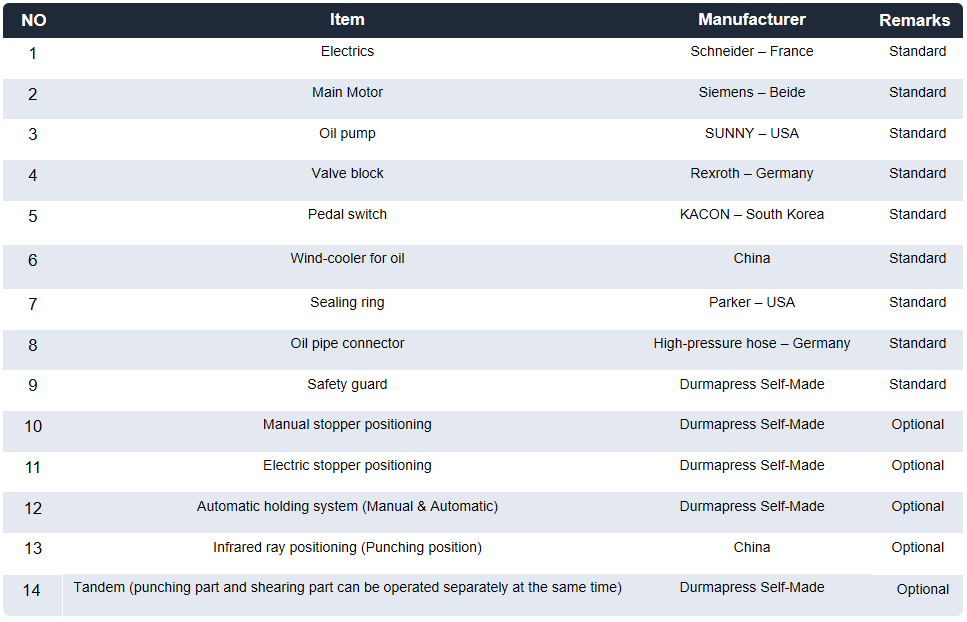

Standard and optional Component

Customize your configuration according to your needs

Standard Features

- A set of punch and die(round hole)

- A set of angle steel blade

- A set of square and round bar blade

- A set of shearing plate blade

- A set of notching blade

- 2 independent hydraulic piston rods and foot-pedal allows two people operating at the same time

- More efficient stroke-control functions of piston rod

- Central lubricating system

- Lighting devices for work

- Motor-driven rear stopper

- 5 independent work-positions

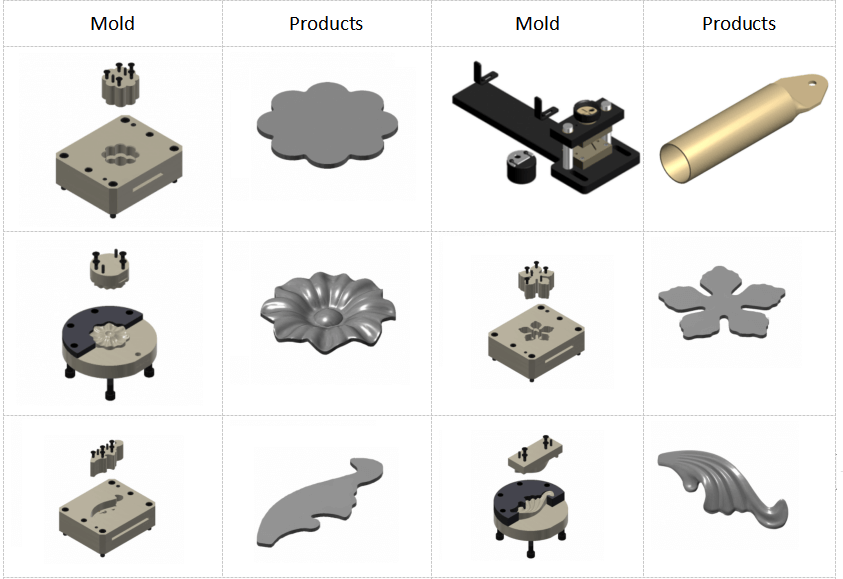

optional Features

- Various toolings for different purposes

- Square, oval, louver punch and die

- Channel shear and I-beam shear

- Conveyor table

- Longer worktable

- Worktable with linear guide

- Φ20, 32, 60mm U type circle

Standard Component

Main Component

Machine Frame

The frame of a Hydraulic Ironworker offers stability, durability, and support for its various components. Its design allows for versatility, enabling the machine to perform multiple functions.

Angle station

This station offers high-capacity angle cutting at both 90° and 45°. For angles between 45° and 90°, the process involves first cutting at 90° and then trimming the flange to the desired angle in the shearing station.

Shearing station

The shearing unit has an adjustable hold-down for various material thicknesses and a shear feed table with guides for precise feeding and miter cutting up to 45° on flat bars or angle flanges.

Punching station

The punch bed area is spacious, featuring a removable front block, ideal for a wide range of punching applications. The standard machine includes a punch table with rules and guides for repetitive work.

Channel Shear

The channel shear offers round or square holes in various sizes to meet customer needs. For added versatility, both functions share the same working position.

Cutting Station

Angle steel, channel steel, flat steel, round bar and square bar can be cut by this machine, vcustomers should choose relevant machine model to cut their varisized products.

Foot Control Panel

The hands-free foot control panel improves safety and efficiency, allowing the operator to activate the machine while keeping both hands on the workpiece, minimizing downtime.

Electrical Parts

Electrical Parts contribute to the safety of the machine by incorporating features such as emergency stop buttons and overload protection. The electrical components also enhance the machine's efficiency, enabling it to perform tasks quickly and effectively.

Product Details

Key advantages

Hydraulic Ironworker

The Hydraulic Ironworker is a versatile machine with hydraulic transmission, offering multiple functions such as cutting, punching, and bending of various steel shapes. It is designed for simple operation, low energy consumption, and minimal maintenance.

ESA S650

- Punching station

- Section cutting station

- Angle Cutting station

- Shearing station

- Notching station

durmapree factory

Watch the Video

Ready to Transform Your metal Process?

Get a personalized quote for your specific needs and discover how the bending machine can enhance your production efficiency and product quality.

- Free consultation with our experts

- Customized solution based on your requirements

- Competitive pricing with flexible financing options

- Comprehensive training and ongoing support