About Us

Durmapress specializes in designing, manufacturing, and selling various metal processing equipment, including bending machines, shears, punches, and laser cutting machines. The company was founded in 2014, with years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

In today’s metalworking industry, automation and multifunctionality have become essential directions for progress. For small and medium-sized metal fabrication workshops, achieving the right balance between cost control, production efficiency, and operational flexibility is crucial. Among the various types of machinery available, the Ironworker Machine stands out for its multifunctional design, compact footprint, and ease of use. It has become an indispensable tool for many metalworking businesses. This article will explore the value, industrial applicability, economic advantages, and development trends of ironworker machines, focusing on their significance for small and medium enterprises.

Equipment Positioning – The Efficient Partner for SMEs

For small and medium-sized fabrication workshops, capital investment in machinery is often constrained by budget and space. Business owners need equipment that provides versatile functionality while maintaining cost efficiency. The Ironworker Machine meets these needs perfectly. By integrating multiple basic metal processing functions into a single system, it allows operators to complete various production tasks within a compact workspace. Its balance between functionality and affordability makes it a strategic asset for small and medium manufacturers seeking to expand their production capabilities.

Application Value – Flexibility Across Production Scenarios

The application value of an ironworker machine lies in its adaptability to diverse production scenarios. Every metalworking workshop has unique requirements—some focus on rapid response to small-batch orders, while others prioritize steady, high-volume output. The ironworker machine, due to its flexible design, fits seamlessly into both types of operations. Whether used for fabricating structural steel components, electrical enclosures, metal furniture, or agricultural equipment parts, it consistently delivers productivity and precision.

Another key benefit for smaller workshops is ease of operation and maintenance. The compact structure and intuitive control system make it user-friendly even for operators with limited experience. This reduces training time and costs while ensuring consistent performance in day-to-day production.

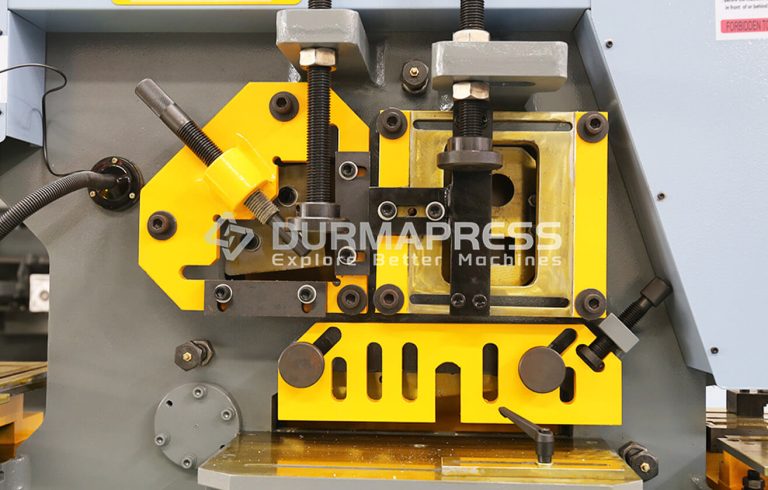

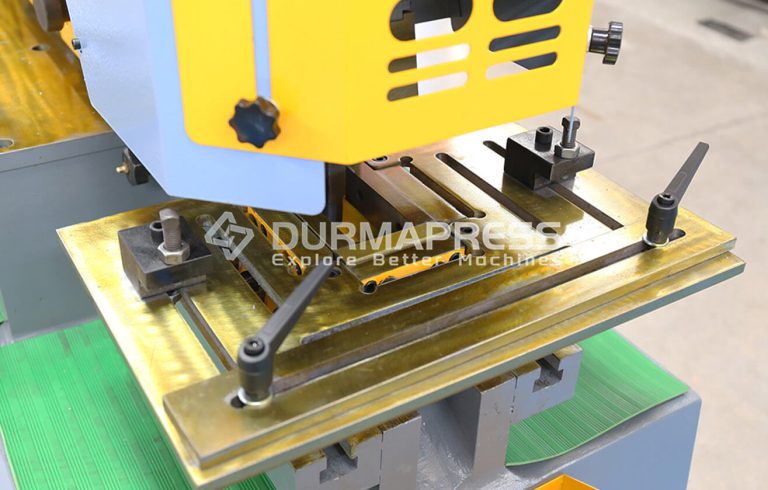

The ironworker machine integrates multiple functions such as punching, shearing sheet metal, angle steel cutting, and profile cutting. It features light weight, compact size, low noise, and high efficiency, making it an ideal piece of equipment for modern manufacturing industries such as metallurgy, bridge construction, communications, and electric power.

This machine is suitable for shearing (cold-state carbon structural steel with a tensile strength of 45 MPa, angle steel, square steel, flat steel, and steel plates). It can also perform special-shaped processing and punching on angle steel and steel plates. Non-ferrous metal products of similar shapes can also be processed. It is particularly suitable for material cutting in industries such as machinery, construction, electric power, light industry, shipbuilding, steel structure, and machining workshops.

The machine consumes little power, delivers strong performance, occupies minimal space, and is lightweight with a compact structure. It offers flexible operation and multi-functional performance while being easy to operate and maintain. It also supports square-hole punching. Note: Always turn off the power when changing molds. The machine is also used in the wind power industry — for processing stair components and pedal parts of wind turbine towers.

The ironworker machine is applicable to:

Steel structure processing.

Elevator cabins and component manufacturing.

Trailer production — spare tire parts, hinges, hooks, pins, and connecting plates.

Construction machinery — processing components for belt conveyors and mixing plants.

Agricultural and livestock machinery — processing parts for threshers and trailer bodies.

Food industry equipment — processing frames and parts for slaughtering machinery.

High and low voltage transmission tower components.

Wind power equipment — processing stairs and pedal parts of wind turbine towers.

General machining — production of embedded parts for construction connections, conveyor supports, and other mechanical components.

Grain and food machinery — processing brackets, shells, and small parts for grain, oil, and starch processing equipment.

Railway freight cars, automobiles, and crane components.

Economic Efficiency – Maximum Productivity with Minimum Investment

In a competitive manufacturing landscape, cost-effectiveness is a decisive factor in equipment selection. The multifunctional nature of the ironworker machine allows companies to perform multiple processes using one piece of equipment, reducing capital expenditure compared to purchasing several specialized machines. Its compact footprint also helps optimize floor space, enabling a more efficient workshop layout.

Moreover, ironworker machines generally feature low power consumption and require minimal maintenance. Their durable construction and reliable performance reduce downtime and extend operational lifespan, ensuring a favorable return on investment. For small and medium enterprises, the combination of affordability, efficiency, and durability translates directly into higher profitability.

Industrial Adaptability – Broad Applications Across Sectors

Ironworker machines are highly versatile and applicable to a wide range of industries. They are frequently used in structural steel fabrication, construction projects, electrical cabinet manufacturing, agricultural equipment, and even metal furniture production. Wherever there is a need for reliable and efficient metal processing, the ironworker machine provides an effective, multi-functional solution.

For manufacturers dealing with multiple product types or small batch orders, the ironworker machine offers exceptional versatility. It allows seamless transitions between various workpieces without requiring extensive setup changes. This flexibility is vital in meeting fluctuating market demands and ensuring quick delivery times—factors that are critical for maintaining competitiveness in the global market.

Technological Upgrades and Intelligent Trends

As manufacturing shifts toward digitalization and smart production, the ironworker machine is also evolving. Modern models often incorporate advanced control systems, digital displays, and monitoring modules. Features such as automatic positioning, electronic supervision, and remote maintenance enhance precision and simplify equipment management, leading to greater productivity and reliability.

In the near future, ironworker machines are expected to integrate more closely with automation systems. When paired with robotic arms or automatic feeding systems, they can form semi- or fully automated workstations. This evolution will empower small and medium enterprises to achieve consistent, high-efficiency production with minimal labor input—aligning with the broader trend of smart manufacturing.

Future Outlook – From Stand-alone Machine to Smart Manufacturing System

As industrial automation continues to advance, future metalworking equipment will become increasingly interconnected and intelligent. The ironworker machine will evolve from a stand-alone tool into a core component of an integrated smart manufacturing system. It will communicate with cutting, bending, and welding equipment through digital networks, enabling data sharing and optimized workflow coordination.

Such integration will allow small and medium manufacturers to achieve efficiency and quality levels comparable to large-scale enterprises, even with limited resources. The ironworker machine will continue to play its role as an “all-round assistant,” empowering workshops around the world to embrace intelligent, efficient, and sustainable manufacturing.

Conclusion

The true value of the ironworker machine lies not only in its multifunctional capabilities but also in its ability to provide flexibility, affordability, and sustainability to small and medium manufacturers. In an era defined by digitalization and automation, choosing the right equipment is the key to staying competitive. As a versatile and reliable partner, the ironworker machine will continue to play an essential role in the evolution of global metal fabrication toward smarter and more efficient production.