About Us

Learn how to adjust blade clearance in hydraulic shears to improve cutting accuracy, edge quality, and blade life for different materials and thicknesses.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Blade clearance adjustment is one of the most critical factors affecting cutting quality, blade life, and long-term accuracy in hydraulic shearing machines.

Whether you are using a swing beam shear or a guillotine shear, understanding hydraulic shear blade clearance adjustment is essential for achieving clean edges and stable performance.

This guide explains what blade clearance is, why it matters, how to set it correctly for different materials, and how adjustment methods differ between swing beam and guillotine hydraulic shears.

What Is Blade Clearance in a Hydraulic Shear?

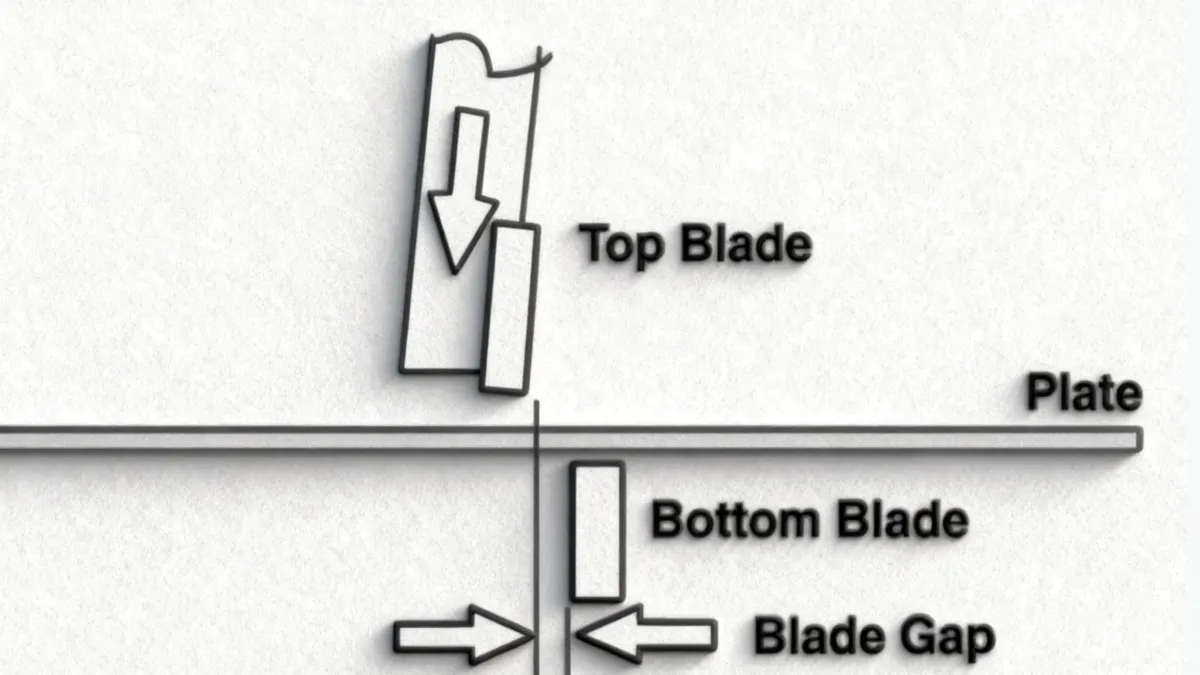

Blade clearance refers to the gap between the upper moving blade and the lower fixed blade during the cutting process.

This clearance is usually expressed as a percentage of the material thickness.

Proper blade clearance allows the material to fracture cleanly along the cutting line.

If the clearance is too small or too large, cutting quality and machine performance will be negatively affected.

Why Blade Clearance Is Critical to Cutting Quality

Burr Formation and Edge Quality

Incorrect blade clearance is one of the main causes of excessive burrs.

- Too small clearance leads to secondary shearing and rough edges

- Too large clearance causes tearing rather than clean shearing

Correct blade gap produces smooth edges with minimal burr height.

Blade Wear and Service Life

Improper clearance increases stress on the cutting blades:

- Small clearance accelerates blade wear and chipping

- Large clearance causes uneven blade loading

Maintaining the correct blade clearance significantly extends blade service life and reduces replacement costs.

Cutting Accuracy and Material Deformation

Blade clearance directly affects:

- Dimensional accuracy

- Flatness of the cut piece

- Deformation near the cutting edge

This is especially important when cutting thicker plates or high-strength materials.

Recommended Blade Clearance for Different Materials

In practice, blade clearance is typically set as a percentage of material thickness, depending on material type and tensile strength.

Recommended Blade Clearance Table

| Material Type | Thickness Range | Recommended Clearance |

|---|---|---|

| Mild Steel (Carbon Steel) | ≤ 3 mm | 5–6% of thickness |

| Mild Steel (Carbon Steel) | 3–10 mm | 6–8% of thickness |

| Stainless Steel | ≤ 3 mm | 6–8% of thickness |

| Stainless Steel | 3–10 mm | 8–10% of thickness |

| Aluminum | ≤ 3 mm | 4–5% of thickness |

| Aluminum | 3–10 mm | 5–6% of thickness |

| High-Strength Steel | ≤ 10 mm | 8–10% of thickness |

Note: These values are general industrial recommendations. Actual settings may vary depending on blade material, cutting angle, and machine rigidity.

Blade Clearance Adjustment Methods

Manual Adjustment in Swing Beam Shears

Most swing beam hydraulic shears use manual or mechanical blade clearance adjustment.

The operator adjusts the clearance using eccentric shafts, adjustment bolts, or mechanical scales.

Characteristics:

- Simple structure

- Lower cost

- Requires operator experience

- Adjustment typically done offline

This method is suitable for workshops where material thickness does not change frequently.

For differences in cutting structure, see our comparison guide on swing beam vs guillotine hydraulic shear.

CNC-Controlled Adjustment in Guillotine Shears

Modern guillotine hydraulic shears often feature CNC-controlled blade clearance systems.

The operator inputs material thickness and type, and the machine automatically adjusts the blade gap.

Advantages:

- High accuracy and repeatability

- Faster setup for mixed production

- Reduced operator dependency

- Ideal for thick plates and precision cutting

This is one of the key reasons guillotine shears are preferred in high-precision fabrication.

Common Blade Clearance Problems and Solutions

| Problem | Likely Cause | Solution |

|---|---|---|

| Excessive burrs | Clearance too large | Reduce blade clearance |

| Rough or torn edge | Clearance mismatch | Adjust according to material |

| Blade chipping | Clearance too small | Increase clearance slightly |

| Sheet deformation | Incorrect clearance or angle | Reset clearance and cutting angle |

Regular inspection and adjustment help maintain stable cutting quality.

How Blade Clearance Influences Shear Selection

Blade clearance control plays an important role when choosing between shear types:

- Swing beam shears are practical for standard thickness ranges with limited material variation

- Guillotine shears offer superior control when cutting different materials and thicknesses in one production cycle

Understanding blade clearance behavior helps buyers make more informed equipment selections rather than relying on machine type alone.

Conclusion

Proper hydraulic shear blade clearance adjustment is essential for achieving clean cuts, long blade life, and stable production performance.

By understanding clearance principles, recommended values, and adjustment methods, operators and buyers can significantly improve cutting results.

This technical knowledge also clarifies why different hydraulic shear designs—such as swing beam and guillotine—perform differently in real-world applications.

FAQ: Hydraulic Shear Blade Clearance Adjustment

What happens if blade clearance is too small?

It increases cutting force, accelerates blade wear, and may cause blade damage.

Is blade clearance the same for all materials?

No. Stainless steel and high-strength materials require larger clearance than mild steel.

Do CNC guillotine shears automatically adjust blade clearance?

Yes, most modern guillotine shears support CNC-controlled blade gap adjustment.

How often should blade clearance be adjusted?

Whenever material thickness or type changes significantly.