In the CNC plasma cutting process, the strong light radiation from the plasma arc poses significant hazards. Typically, these risks are mitigated by using protective eyewear or operating in fully enclosed workshops, especially for high-power plasma cutting equipment. This paper focuses on the correlation between the five core parameters of CNC plasma cutting machines and the formation of light radiation hazards.

The five critical parameters include

Arc Height: The height of the plasma arc significantly affects cutting quality, as it determines the perpendicularity of the cut surface. Improper arc height selection can result in non-vertical cuts or severe deviations, with thicker plates requiring shorter arc heights compared to thinner ones.

Arc Pressure: Adjusting the arc pressure regulates the output plasma energy. Higher arc pressures correspond to increased plasma energy output.

Delay: Primarily used for piercing, delay refers to the time required for the machine to move after piercing to ensure proper cutting. Thicker plates typically require longer delay times compared to thinner plates.

Each of these parameters plays a crucial role in controlling the cutting

About Us

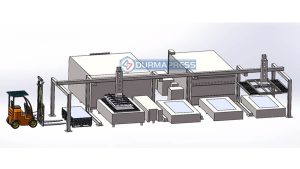

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Recent Posts

Follow Us

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.