About Us

Durmapress specializes in designing, manufacturing, and selling various metal processing equipment, including bending machines, shears, punches, and laser cutting machines. The company was founded in 2014, with years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

In modern sheet metal fabrication, precision is not just an advantage — it is a necessity. As global manufacturing standards continue to rise, the ability to produce accurate, repeatable, and high-efficiency results defines the competitiveness of every metalworking enterprise. While the spotlight often falls on cutting or bending technologies, one silent contributor ensures consistency in every product dimension: the backgauge system.

The backgauge, though seemingly a secondary structure, serves as the “coordinate reference” of bending and shearing operations. Whether used in a CNC press brake or a hydraulic shear, it determines the exact position of the workpiece and guarantees that every bend or cut is precisely aligned. As automation and intelligent control redefine modern production, the backgauge system has transformed from a simple mechanical stop into an integrated, smart, and highly responsive component — one that bridges precision and efficiency in metal processing.

The Function of the Backgauge System

At its core, the backgauge system determines how accurately a machine can position a sheet of metal before processing. In a press brake, it defines the bending length and angle consistency; in a shearing machine, it ensures exact cutting dimensions. This precision positioning function, once manual and operator-dependent, has evolved into a sophisticated, servo-driven system synchronized with the machine’s CNC control.

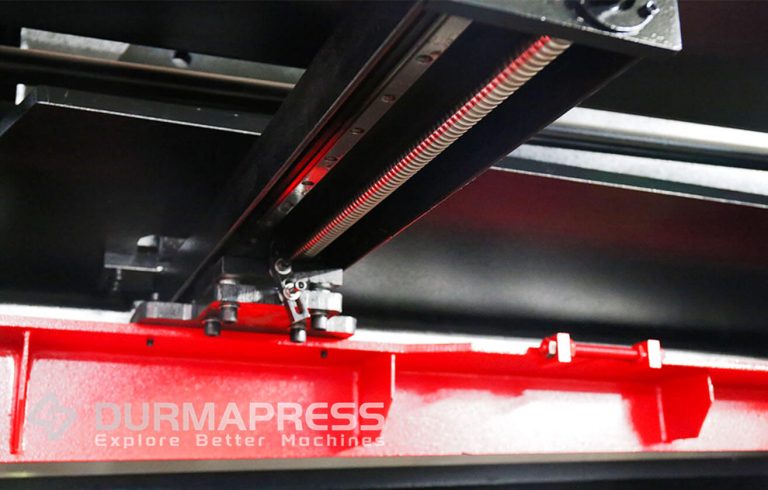

A modern backgauge operates through linear motion guided by high-precision ball screws or gear-driven mechanisms. Controlled by advanced servo motors and feedback sensors, it allows for micrometer-level positioning repeatability. As a result, operators can perform complex bending sequences or high-speed cutting cycles with minimal manual intervention — improving productivity and drastically reducing the margin for error.

From Manual to Intelligent: The Evolution of Backgauge Design

In the early generations of press brakes and shears, backgauges were entirely manual. Operators used handwheels or mechanical stops to set positions, relying heavily on experience and visual estimation. This method was slow, inconsistent, and unsuitable for mass production.

The introduction of numerical control (NC) marked a turning point. Machines began integrating motorized adjustment, allowing operators to input values that automatically repositioned the backgauge. However, it was with the rise of CNC technology that the backgauge truly became a smart system.

Today’s CNC backgauges communicate directly with the control unit, automatically adjusting positions according to the programmed sequence. They can calculate optimal positioning paths, compensate for material deformation, and even adapt to various tooling configurations. This shift represents not only an upgrade in mechanical capability but also a leap in the intelligence of the entire production workflow.

Structure and Components: Precision Engineering in Every Detail

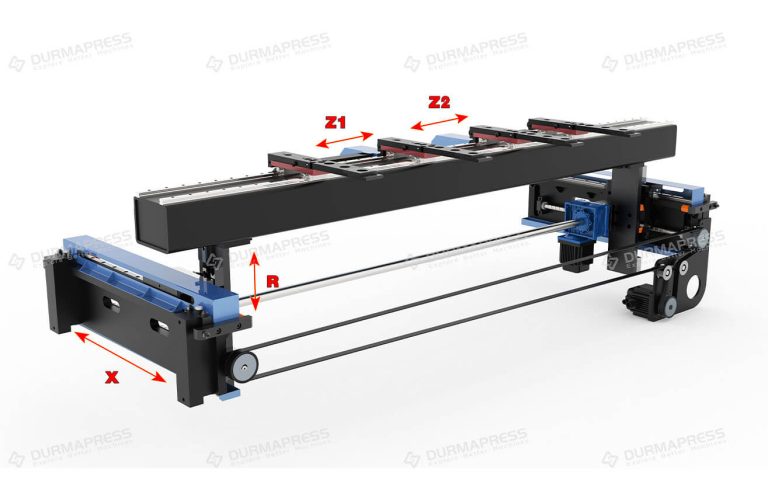

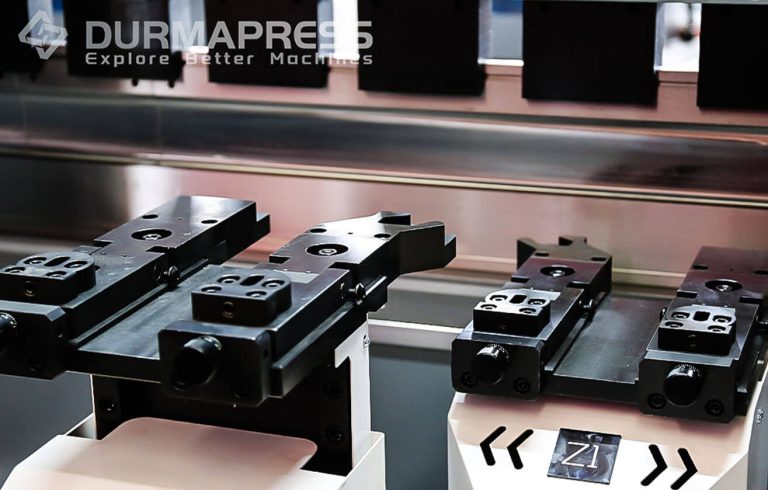

Though compact in size, the backgauge system embodies complex coordination between multiple components: linear guideways provide smooth and rigid motion; servo motors and drive units deliver fast, precise, and repeatable positioning; screw transmission or rack systems convert rotary motion into linear displacement with minimal backlash; CNC controller integration synchronizes motion commands with bending or cutting sequences; stop fingers define the workpiece reference edge and are now adjustable, modular, and sometimes automatically retractable. Each of these elements contributes to achieving the high repeatability required for modern fabrication — often within ±0.01 mm tolerance.

Performance Advantages in Modern Production

An intelligent backgauge system delivers measurable benefits that directly impact efficiency, precision, and operator comfort. It provides high accuracy and repeatability, increased productivity through automated positioning, ease of operation via CNC programming, flexibility through multi-axis configurations, and reduced operator fatigue by minimizing manual adjustments.

An intelligent backgauge system delivers measurable benefits that directly impact efficiency, precision, and operator comfort. It provides high accuracy and repeatability, increased productivity through automated positioning, ease of operation via CNC programming, flexibility through multi-axis configurations, and reduced operator fatigue by minimizing manual adjustments.

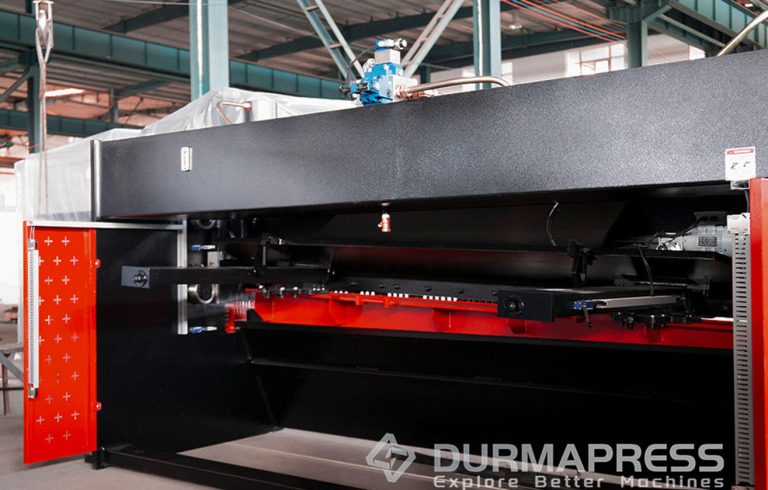

Backgauge Systems Across Different Machines

Although the principle of operation remains consistent, backgauge design and functionality vary depending on the type of machine. In press brakes, the backgauge determines the exact bending line position. Advanced systems allow for automatic adjustment of height (R-axis), lateral position (Z-axis), and even angle correction through feedback loops — crucial for complex parts requiring multiple bends in different directions. In shearing machines, the backgauge defines the cutting length, ensuring that every sheet section maintains consistent dimensions. In high-speed production, automatic retract functions prevent material interference and enable continuous feeding.

Adjusting the backgauge on a press brake depends primarily on the CNC system your machine is equipped with, as well as whether it has a servo motor or a frequency converter (VFD), which are the only systems that can adjust the speed. Typically, the backgauge is adjusted on the CNC system, such as the DA52. Simply enter the desired values for the press brake and click "Run." The backgauge will automatically adjust to the desired values. This is how the backgauge is adjusted.

If you need to adjust the backgauge left, right, up, or down, this also depends on the system your press brake is equipped with. For example, on a 3+1-axis electro-hydraulic servo press brake, manual adjustment of the backgauge is required. On a 4+1-axis electro-hydraulic servo press brake, manual adjustment of the backgauge is required; the backgauge is adjusted up and down on the CNC system. The backgauge can be adjusted left or right using a joystick on the foot switch.

The shearing size of a CNC shearing machine is primarily dependent on the backgauge. To achieve a certain level of dimensional accuracy, the backgauge should be properly adjusted. This prevents problems and ensures the normal operation and optimal performance of the equipment. The backgauge of a CNC shearing machine is adjusted via the CNC panel. Therefore, automatic adjustment depends primarily on proper settings and proper operation of the panel. Generally, click Data Input, enter the backgauge data, press Auto, and then Start. The backgauge automatically adjusts to its proper position.

When cutting steel plate with a CNC shearing machine, the cutting thickness is affected by the blade gap. If the gap is 1 to 3 mm, the adjustment should be 1 to 2 mm. If the gap is 4 to 10 mm, the adjustment should be 3 to 5 mm.

Integration with CNC Systems: The Intelligence Core

The most significant leap in backgauge evolution lies in its full integration with CNC systems. Instead of working as a separate mechanical unit, the backgauge now acts as an intelligent subsystem continuously communicating with the main controller. Through servo synchronization and real-time feedback, the CNC can calculate the best positioning sequence for each operation. Some systems even perform automatic correction, compensating for deviations caused by material springback, thickness variation, or die wear.

This level of automation allows operators to move seamlessly from one production order to another, reducing downtime and increasing machine utilization. Integration with 3D simulation software enables pre-programmed bending sequences, minimizing trial runs and ensuring first-part accuracy.

Maintenance and Reliability: Designed for Longevity

Despite its technological sophistication, the backgauge system is designed for reliability and ease of maintenance. Precision ball screws and guide rails are often pre-lubricated and sealed, requiring minimal service. Servo systems incorporate self-diagnostic functions to detect abnormal loads or alignment issues. Regular calibration ensures sustained accuracy, while modular design allows for quick component replacement when necessary. Many manufacturers now offer remote diagnostic support, allowing service engineers to check backgauge performance data online — an essential capability for global users who demand quick response times.

The Future of Backgauge Technology: Smart Manufacturing Integration

As Industry 4.0 transforms the global manufacturing landscape, backgauge systems are evolving beyond mechanical precision into the realm of digital intelligence. Future designs will increasingly focus on connectivity, data analytics, and adaptive learning. Innovations include IoT connectivity for real-time monitoring, AI optimization for predictive positioning strategies, digital twin simulation for performance forecasting, and collaborative automation integrating robotic arms for synchronized production. These advancements will enable factories to achieve higher autonomy and efficiency, marking a new era in precision sheet metal fabrication.

Why the Backgauge Reflects a Machine’s True Quality

Among all visible specifications — tonnage, power, or frame size — the quality of a machine’s backgauge often reveals the true level of its engineering sophistication. A stable, precise, and responsive backgauge system represents more than just convenience; it reflects a manufacturer’s commitment to precision manufacturing and user-centered design. For small and medium enterprises, investing in a high-performance backgauge means faster setup, more accurate results, and stronger competitiveness. For large-scale manufacturers, it provides the stability and consistency required for high-volume operations.

Conclusion

The backgauge system may operate behind the scenes, but its contribution to the performance of modern sheet metal machinery is undeniable. From simple manual stops to intelligent, multi-axis servo systems, its evolution mirrors the broader journey of manufacturing — from labor-intensive processes to data-driven precision engineering.

In an era defined by efficiency, automation, and digital control, the backgauge stands as a symbol of hidden sophistication — transforming every bend, every cut, and every movement into an act of engineered precision. As manufacturers like Durmapress continue to refine and innovate backgauge technology, the future of metal fabrication will not only be faster and smarter but also infinitely more precise.