In the Brazilian market, machinery products must comply with relevant local regulations to be legally put into production and use. NR 12 is a key regulation specifically addressing the safety of machinery and work equipment in the workplace. This article details the Brazilian NR 12 machinery product certification process to help companies successfully complete the certification process.

About Brazilian Regulatory Standards

Brazilian Regulatory Standards (NRs) are issued by the Brazilian Ministry of Labor and Employment (MTE) to regulate the workplace safety of machinery and equipment. Their purpose is to ensure compliance with the Brazilian Constitution and labor laws. Currently, Brazil has promulgated 36 NRs, with NR 12 specifically addressing the safety of machinery and work equipment in the workplace. NR 12 and its annexes provide technical references, basic principles, and protective measures, specifying minimum requirements for preventing occupational diseases and accidents during design and use, thereby ensuring the safety and health of workers. The Brazilian NR compliance process primarily consists of two phases: pre-compliance procedures and compliance testing and verification.

Pre-compliance procedures

Before the customer specifies the delivery node of the line equipment, the certification service provider must complete the NR compliance pre-compliance procedures for the design and manufacturing process of the manufacturer's equipment to ensure the end customer's approval of the equipment delivery. At the same time, it must avoid making disruptive changes in technical solutions and mechanical designs or adding a large amount of hardware at the installation site.

The certification service provider will provide a risk assessment analysis based on Brazilian NR requirements. Based on this assessment, they will recommend safety improvement measures, safety procedures, and emergency plans. They will also provide requirements for the installation and operation of personal protective equipment to ensure NR compliance throughout the project. Essential training on basic standards will also be provided during the certification process.

The certification service provider guides and collaborates with manufacturers in the necessary NR certification process selection analysis (applicable standards, brands, technical specifications, etc.). They are also responsible for the production and output of NR certification-related materials and documentation, including but not limited to manufacturer-specific systems (components, equipment), purchased parts, purchased standard systems (components, equipment), and purchased non-standard systems (components, equipment). For the entire NR certification process, if language requirements are present, the service provider is responsible for providing the required documentation in Chinese, English, and Portuguese. However, if the manufacturer's original design drawings, operating instructions, and other documents require a specific language, these can be provided by the manufacturer.

During the manufacturing and assembly (domestic part) stage, we will be on site (if necessary) to conduct necessary packaging and pre-shipment acceptance of the line equipment to ensure NR compliance of the design and manufacturing process.

Before the equipment is shipped, the equipment design and manufacturing ART need to be provided.

Compliance testing and acceptance confirmation

At this stage, the certification service provider must provide a qualified ART engineer registered with CREA to conduct inspection and testing at the Brazilian installation site.

The certification process includes the evaluation and review of the installation or construction plan and process supervision before the local installation and construction in Brazil, as well as the on-site construction and installation safety assessment and risk analysis report, and the proposal of corresponding control measures and safety recommendations to ensure that the operation and installation are carried out on site in accordance with the review requirements and safety standards during the design.

The certification process includes on-site inspection and assessment, confirmation of the compliance of on-site installation preparation and implementation conditions, and necessary safety training and supervision for on-site installers.

After the installation is completed, the ART engineer submits an installation technical report describing the installation process and compliance.

Certification completed

Ultimately, thanks to the service and cooperation of the certification service provider, the manufacturer's production line (equipment) complies with Brazil's NR requirements and receives CREA-approved ART documents (Design and Manufacturing ART and Installation ART). The line can then begin production according to local requirements. Throughout the certification process, the certification service provider is required to rationally allocate personnel and carry out corresponding tasks according to the overall project milestones. The project is concluded after passing the NR certification registration and obtaining the ART. In short, Brazil's NR 12 mechanical product certification process is rigorous and standardized. Companies must strictly adhere to the requirements of each step and work closely with professional certification service providers to ensure their products pass certification and enter the Brazilian market.

How do DURMAPRESS's press brakes meet NR12 "line by line"?

The following 10 items correspond to the key clauses of NR12 and are broken down one by one.

1.Risk Analysis and PL e Safety Loop

DURMAPRESS used the Sistema DA58Tx 2D graphical programming system during the planning phase to conduct a HAZOP and FMEA analysis of 28 potential hazardous points (mold clamping, backgauge operation, laser protection, and emergency stop circuit).

The safety circuit adopted the highest PL e / Category 4 according to EN ISO 13849-1: dual-channel redundant safety relays + servo drive STO (Safe Torque Off), ensuring shutdown even in the event of a single point of failure.

2. Mechanical protection and mold safety

Standard DSP Laser Protection monitors laser radiation intensity and position in real time, with a light curtain response time of less than 15 ms. Upon detecting a foreign object, the main motor and hydraulic pump are simultaneously shut off.

Utilizing the WILA Safety-Click® quick-clamping system, mold changes snap into place with a snap, eliminating the risk of spatter caused by loose bolts.

3. Electrical safety

The entire electrical cabinet utilizes genuine Schneider components, meeting EN 60204-1 requirements for leakage, short-circuit, and overload protection.

The control cabinet boasts an IP54 protection rating, ensuring stable operation even in Brazil's hot and humid environment.

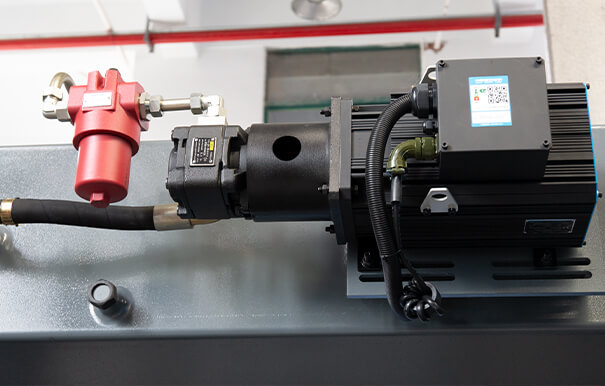

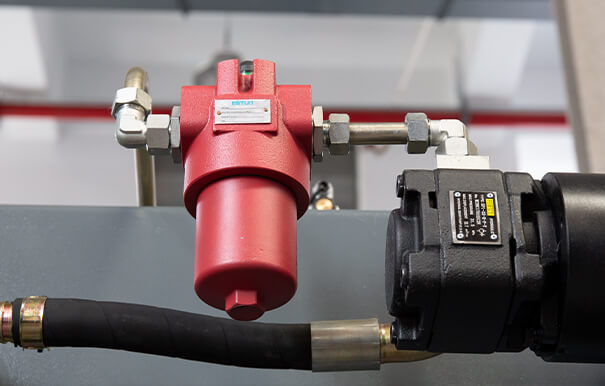

4. Hydraulic system safety

A two-way cartridge valve and hydraulically controlled check valve combination ensures immediate pressure relief upon power failure.

The high-pressure oil pipe is wound with four layers of steel wire, with a burst pressure of ≥1000 bar, far exceeding the three-fold safety factor specified in EN 12622.

5. Ergonomics and accessibility

The extended front support arm and adjustable height stop reduce operator bending; the 15" color touch screen has a 30° tilt angle and meets ISO 9241 eye fatigue standards.

6. Noise and vibration

The servo motor + servo pump technology reduces no-load noise from the traditional 78 dB(A) to 68 dB(A), far below the NR15 limit of 85 dB(A).

7. Maintain security

The modular design of the full protective cover allows for quick assembly and disassembly in 3 minutes; key lubrication points are centrally located externally, allowing maintenance without entering hazardous areas.

8. Training and Documentation

Included with the following: Risk Assessment Report, Operation Manual, Maintenance Manual, Training Record Sheet in Brazilian Portuguese.

9. Third-party certification

Conclusion: Safety is not a cost, but the highest level of competitiveness

The stringent NR12 standard may seem to raise the bar, but in reality, it's effectively discouraging low-quality, low-price competitors, allowing companies that truly prioritize safety, quality, and compliance to gain a larger platform. DURMAPRESS consistently produces high-quality machines and welcomes inquiries from customers worldwide.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.