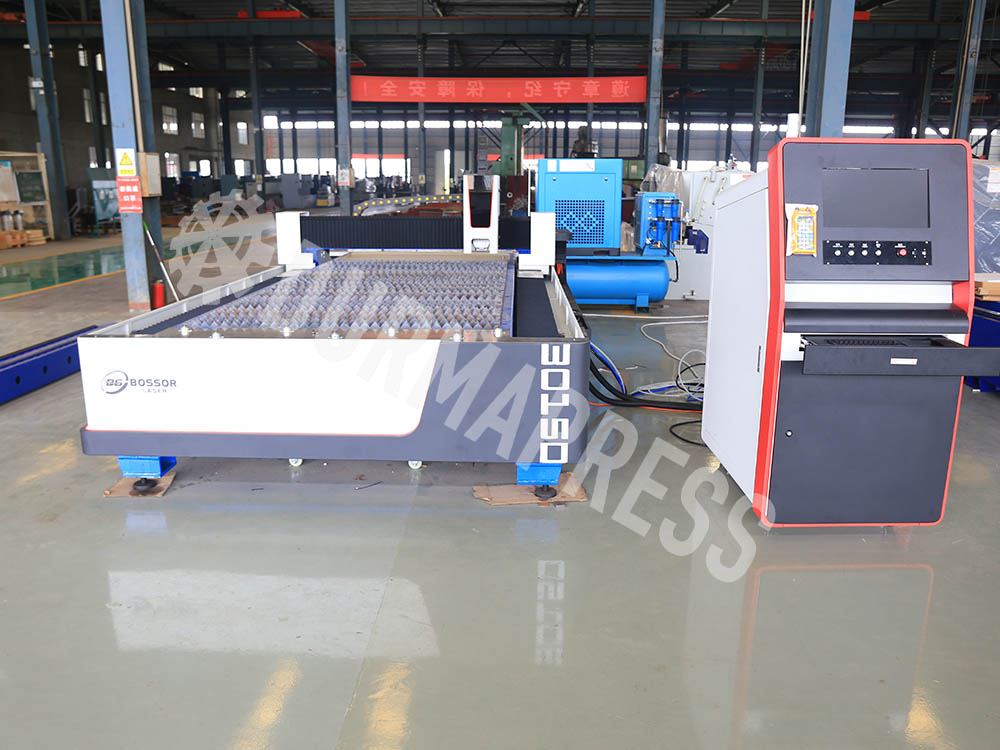

1000W metal laser cutting machine processing is an invisible beam instead of the traditional mechanical knife, with high precision, cutting fast, not limited to the cutting pattern restrictions, automatic typesetting save materials, smooth incision, low processing costs, will gradually improve or replace the traditional metal cutting process equipment. With the growing strength of the metal processing industry, the metal laser cutting machine can not cut all metal materials?

① stainless steel cutting

Laser cutting is an effective tool for the manufacturing industry which uses stainless steel sheet as the main component. Under the strict control of heat input in laser cutting process, the cutting heat affected zone can be limited to become small, so as to effectively maintain the good corrosion resistance of such materials. Our laser cutting machine can cut the maximum thickness of about 10mm. Thin sheet cutting seam is small, the cutting surface is smooth without burr, and can be widely used in the advertising industry.

② carbon steel cutting

Metal laser cutting machine cutting maximum thickness of 25mm carbon steel plate, the use of advanced laser technology, good beam quality, small slit, and cutting surface is smooth, cutting 5mm below the carbon steel plate only need to blow air, without blowing oxygen, greatly saving the user the cost of using oxygen.

③ The cutting of copper materials

Why do you need to add auxiliary gases to cut highly reflective metal materials? When the metal laser cutting machine cuts metal copper, the auxiliary gas and the material are added to react at high temperature, increasing the cutting speed, such as the use of oxygen can achieve the effect of combustion. Nitrogen in the laser cutting equipment, is to improve the cutting effect of an auxiliary gas, for the copper material below 1mm, the use of metal laser cutting machine can be processed.

④ Other metal material cutting

Laser cutting machine is suitable for non-contact cutting, hollowing and punching all kinds of sheet metal. With the advantages of high precision and high speed, it has become the development direction of sheet metal processing technology.