What is a press brake robot

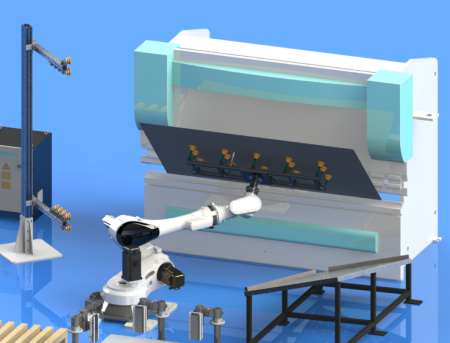

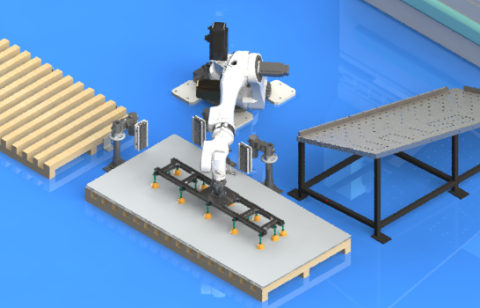

The press brake robot is an industrial robot with high precision, high efficiency and high automation. It is mainly used for the press brake processing of metal sheets, and can realize the production of metal products of various complex shapes. The press brake robot integrates a variety of advanced technologies such as robotics, CNC technology, and sensor technology. It has powerful data processing and control capabilities and can accurately complete press brake operations.

Basic functions of press brake

- Bending: press brake the metal sheet according to the preset press brake angle and press brake radius.

- Cutting: Cut metal sheets to fixed lengths to meet different length requirements.

- Punching: punching holes of various shapes on metal plates to meet structural design requirements.

- Flanging: Flanging the edges of metal sheets to improve the strength and stability of the sheets.

- Mold replacement: According to different processing needs, the corresponding molds are replaced to realize the processing of metal products of various shapes.

Why combine robots for press brake work

- Improve production efficiency: The press brake robot adopts advanced control systems and technologies to achieve high-speed and high-precision press brake operations. During the production process, the robot can work continuously and stably, avoiding errors and pauses caused by human factors, and greatly improving production efficiency. In addition, the press brakerobot can also perform continuous operations without rest, further improving production efficiency.

- Reduce labor intensity: press brake robots replace manual operations, freeing workers from heavy press brake work and reducing workers' labor intensity. Robots can work in harsh environments, ensuring the improvement of workers' working environment and improving work comfort. At the same time, the robot can cope with dangerous and complex environments, ensuring the safety of workers.

- Improve product quality: The press brake robot adopts a precise control system and can achieve precise press brake operations. During the production process, robots can ensure the consistency of product size and shape, improving product quality. In addition, robots can also perform complex press brake operations to make product shapes more diverse and meet the needs of different customers.

- Reduce production costs: press brake robots have a high degree of automation and reduce labor costs. The robot can work continuously 24 hours a day, reducing production costs. At the same time, the robot has high press brake accuracy, reducing the scrap rate and rework rate, further reducing production costs.

- Flexible response to market demand: press brake robots have high flexibility and can quickly adjust production processes and parameters to meet the diverse needs of the market. When facing market changes, companies can quickly respond to market changes and improve their market competitiveness by adjusting their robot production processes.

- Realize intelligent manufacturing: press brake robots can cooperate with other intelligent manufacturing equipment to build modern production lines. Through the Internet of Things, big data and other technologies, information collection and data analysis in the production process are realized to provide decision-making support for enterprises. At the same time, robots can work collaboratively with other equipment to achieve the upgrading and development of the manufacturing industry and promote the development of my country's intelligent manufacturing field.

How a press brake robot works

working system

The press brake robot is a robot system with high precision, high efficiency and automation. It is widely used in metal processing, manufacturing and other fields. The press brake robot realizes automatic press brake operations on metal sheets through programming and control systems, greatly improving production efficiency and reducing workers' labor intensity. Below, we will introduce in detail how the press brake robot works and the beat analysis of its working system.

press brake robots are mainly composed of control systems, execution systems, sensor systems and auxiliary systems.

Control system: The control system is the core part of the press brake robot and is mainly responsible for program operation, data processing, fault diagnosis and other functions. Through the control system, the robot can accurately complete the preset press brake tasks.

Execution system: The execution system includes the robot body and driver, and is mainly responsible for realizing the movement and force control of the robot. The execution system accurately completes the press brake action according to the instructions of the control system.

Sensor system: The sensor system is used to monitor the working status of the robot in real time, such as displacement, speed, force, etc., to ensure that the robot bends according to preset parameters.

Auxiliary system: The auxiliary system includes loading and unloading equipment, conveyor belts, etc., and is responsible for feeding metal sheets to the press brake robot for processing.

Work flow of press brake robot

- Preparation work: The worker places the metal plate on the loading and unloading equipment, enters the press brake parameters, and sets the press brake sequence and angle.

- Programming: The control system generates corresponding processing programs based on the input press brake parameters.

- press brake process: The execution system drives the robot to complete the press brake action according to the programming instructions. The sensor system monitors the working status in real time to ensure press brake accuracy.

- End the work: After the press brake is completed, the robot sends the metal plate out of the work area to complete a press brake operation.

- Rhythm analysis of press brake robot working system

- Beat definition: Beat refers to the time required for the robot to complete a complete press brake operation. The shorter the cycle time, the higher the production efficiency.

Factors affecting rhythm

- Movement speed of the robot: The faster the movement speed, the shorter the beat, but both press brake accuracy and safety must be taken into consideration.

- Number of bends: The greater the number of bends, the longer the cycle time, but it will affect production efficiency.

- press brake sequence and angle: Reasonable press brake sequence and angle can reduce unnecessary movements and improve the cycle time.

- Loading and unloading time: The shorter the loading and unloading time, the shorter the cycle time. Production efficiency can be improved by optimizing loading and unloading equipment and methods.

- Through the above analysis, we can understand the basic principles, processes and rhythm analysis of the press brake robot's work. In practical applications, optimizing the beat of the press brake robot and improving production efficiency are the focus of enterprises.

The future prospects of bending robots

The bending robot is a highly automated robotic equipment with a wide range of applications and broad future prospects. Under the current technological development trend, bending robots are mainly used in the following industries:

Automobile manufacturing industry

With the rapid development of my country's automobile industry, the demand for automated production equipment continues to increase. The application of bending robots in this area is mainly reflected in the bending, welding and assembly of body parts. By introducing bending robots, automobile manufacturing companies can improve production efficiency, reduce production costs, and improve product quality.

Electronic product manufacturing industry

In the production process of electronic products, the bending process is also indispensable. Bending robots can bend metal sheets of various complex shapes to provide stable structural support for electronic products. As my country's electronic product manufacturing industry continues to develop, the demand for bending robots will continue to grow.

achitechive

In recent years, the demand for steel structures in my country's construction industry has increased year by year. Bending robots can precisely bend metal sheets and provide various complex steel structures for the construction industry. In this field, the application prospects of bending robots are very broad.

New energy industries, such as solar energy, wind energy, etc., have a greater demand for processing metal materials. Bending robots can efficiently complete the bending processing of metal materials and provide a stable supply of raw materials for the new energy industry.

The medical device industry has high requirements for the processing accuracy of metal parts. Bending robots can achieve high-precision bending of metal sheets and provide high-quality metal parts for the medical device industry.

As the requirements for product quality in various industries continue to increase, bending robots need to improve bending accuracy further to meet diversified production needs.

Through technological innovation, we can improve the production efficiency of bending robots and reduce production costs to meet the needs of market competition.

In the future, bending robots will develop in an intelligent and networked direction, achieve autonomous learning, independent decision-making, and independent control, and improve the automation level of production lines.

To improve production safety, bending robots will develop in human-machine collaboration, realizing collaborative operations between robots and human workers and reducing production risks.

In the context of increasing environmental awareness, bending robots need to develop in a green and environmentally friendly direction to reduce energy consumption and environmental pollution.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.