Peruvian Customer Successfully Ordered Hydraulic Press Brake and Guillotine Shearing Machine

Today, we are thrilled to share that a client from Peru has successfully purchased two of our flagship products: a highly efficient hydraulic press brake and an advanced hydraulic guillotine shearing machine.

Client Background

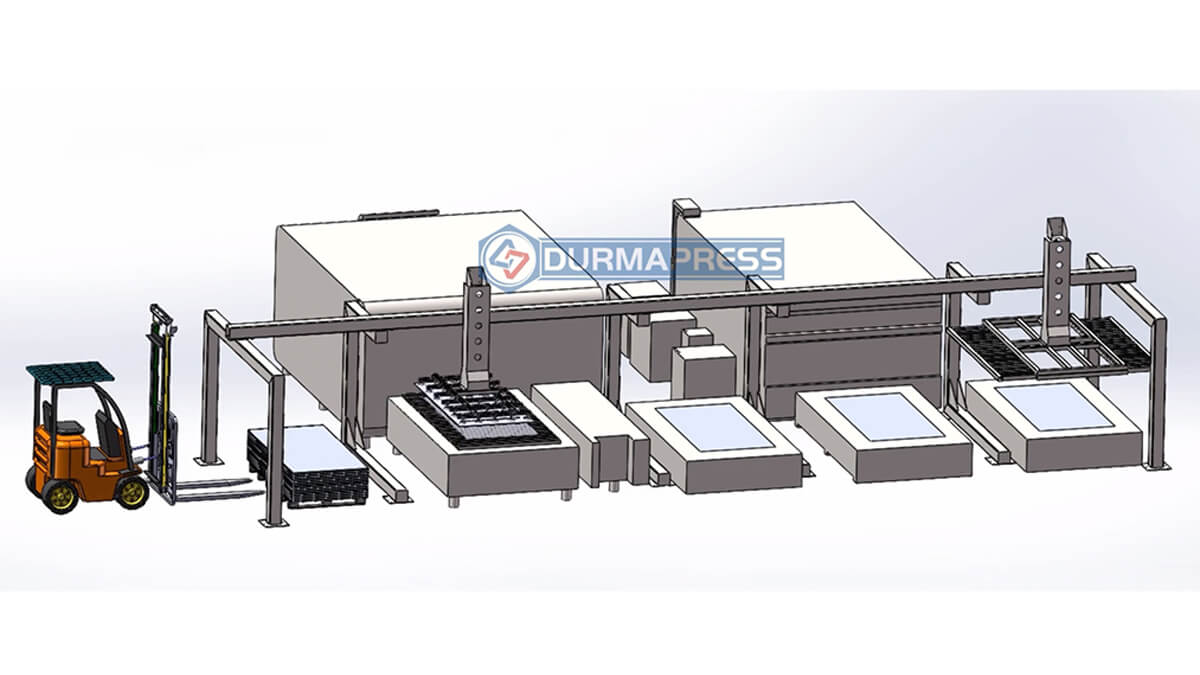

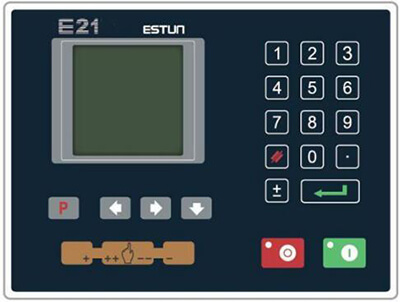

Our Peruvian client is renowned in the local manufacturing sector for providing high-quality metal processing services. To expand their business scope and enhance production efficiency, they decided to introduce advanced machinery. They learned about our company through our website, where we are presented as a professional sheet metal machinery manufacturer. Our client was not only impressed with our bending and laser machines but also with the scale of our factory, the quality of our products, and our professional services. The bending machine, equipped with advanced hydraulic and CNC technology, ensures optimal precision and accuracy. Our hydraulic guillotine shearing machine offers precise and high-quality shearing, meeting their needs for cutting steel, aluminum, or other metals with the required precision and speed. They eventually chose to order the WC67K-200T2500/E21 hydraulic bending machine and the QC11Y-162500/E21S guillotine shearing machine.

Product Introduction

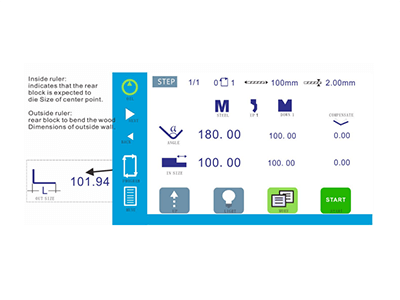

Hydraulic Press Brake (WC67K-200T2500/E21): The Hydraulic Press Brake with E21 Controller, with its user-friendly control unit, rigid body frame, impeccable design, high efficiency, multiple tool usage solutions, adherence to top CE safety standards, and suitable price range, stands out as the best-in-class world leader. It is ideal for bend-sensitive, energy-efficient solutions.

Guillotine Shearing Machine (QC11Y-162500/E21S): This machine has a shearing thickness of 16mm and a shearing width of 2500mm. The main motor power is 22kw, and the shearing angle is 0.5-2.5°. Renowned for its precision, speed, and ability to handle large metal thicknesses, this shearing machine is an indispensable tool for any operation requiring precise metal cutting.

Customer Experience

The client is extremely satisfied with the performance and output of these two machines. They particularly appreciated the advantages of operational efficiency, precision, and adaptability to complex processes. The introduction of these machines significantly enhanced their production capabilities while also reducing production costs. Moreover, the Peruvian client expressed gratitude for our professional after-sales service and hopes to maintain cooperation with us. They are also keen to promote our bending and shearing machines locally. We are deeply grateful for the client's trust and support!

This collaboration not only strengthened our connection with the Peruvian market but also proved our commitment to providing high-quality products and services. We look forward to establishing more such successful collaborations globally.