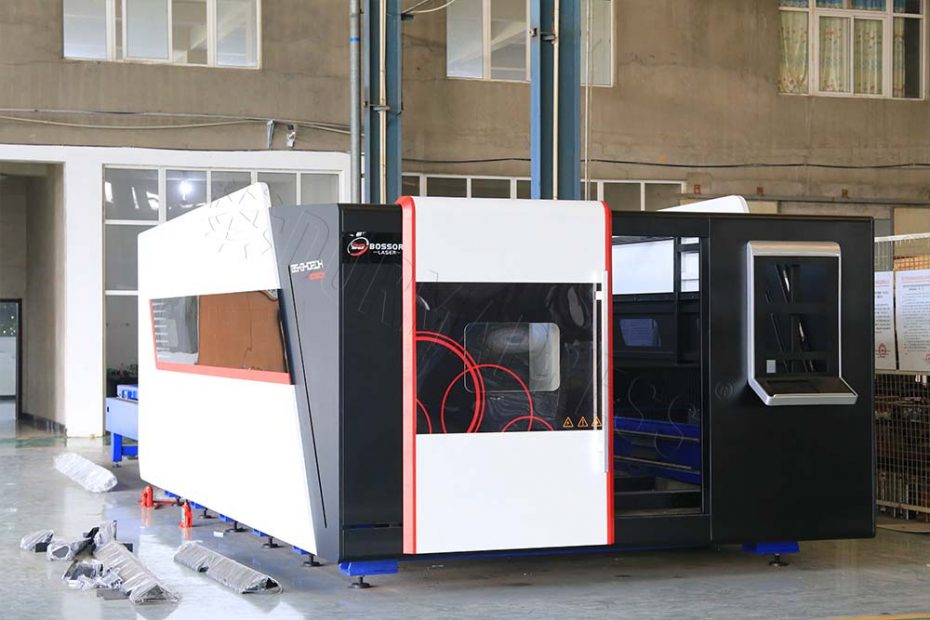

Installation method of focusing mirror of 2kw sheet tube fiber laser cutting machine

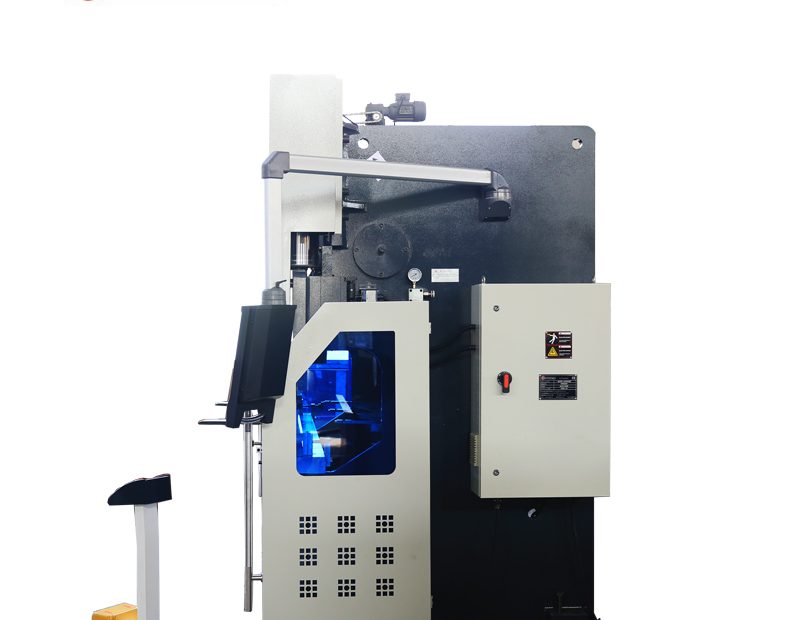

2kw sheet tube fiber laser cutting machine focusing mirror after a long time of use, if there is a film, dents, scratches and other phenomena will make the function of laser equipment at a great discount.If you want the laser cutting machine to work properly, you need to replace the lens in time.So, how should we install the focusing lens correctly? Installation method of focusing mirror of 2kw sheet tube fiber laser cutting machine: 1. Put the protective film of… Read More »Installation method of focusing mirror of 2kw sheet tube fiber laser cutting machine