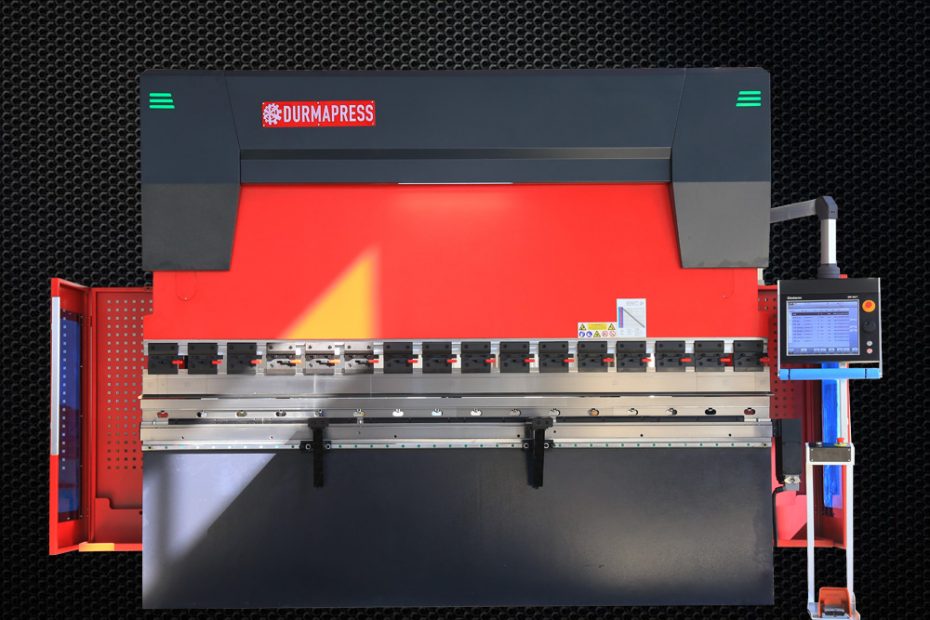

E300P CNC System of bending machine with Touch screen

E300P The full touch bending machine numerical control device is a new generation of CNC system for conventional bending machine developed and produced by ESTUN Automation Co. Ltd, The CNC adheres to the tradition of stable and reliable quality and superior performance of ESTUN CNC products, it integrates the advanced technology of delem,Optimized operation interface,The full touch operation mode is adopted to improve the operation convenience of customers,The control function of the machine tool is enhanced, and the working efficiency… Read More »E300P CNC System of bending machine with Touch screen