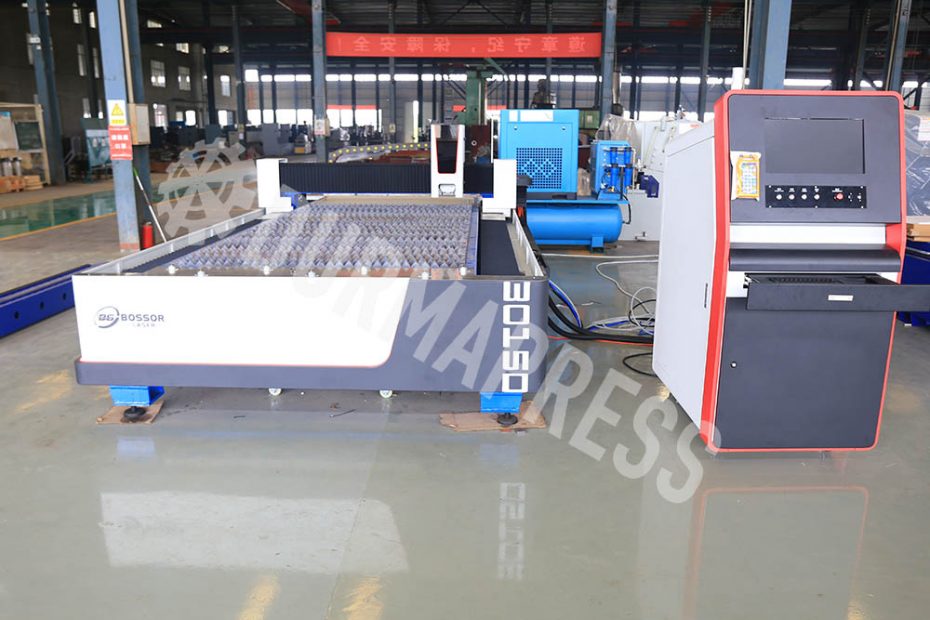

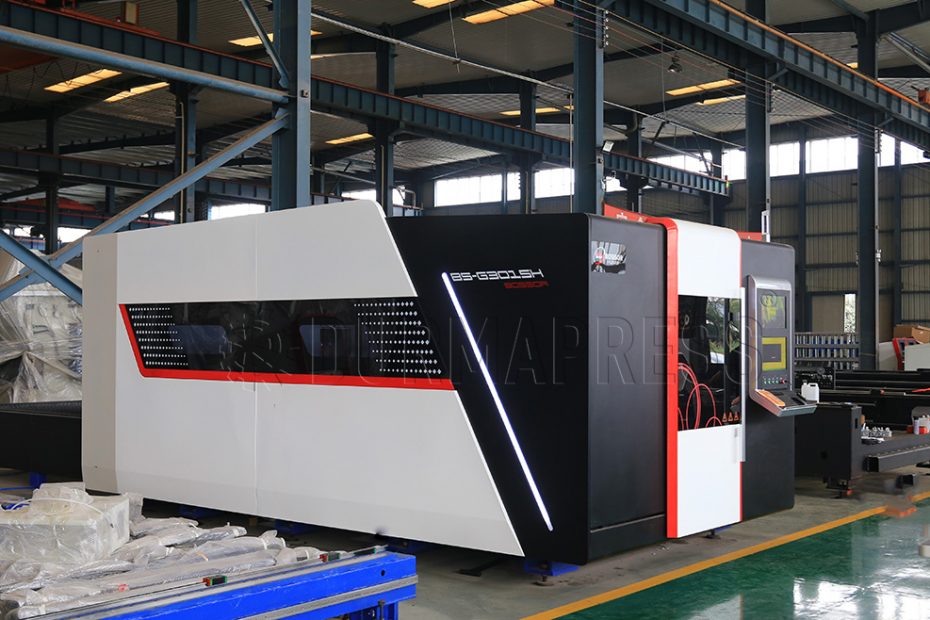

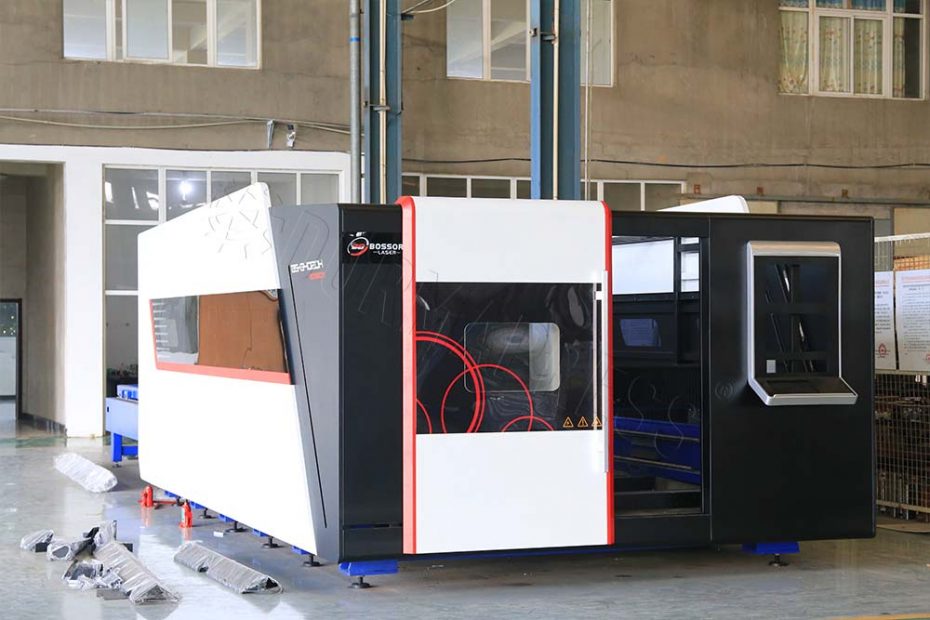

BS3015T-3000W Laser cutting machine common six problems and treatment methods

1. BS3015T-3000W Laser cutting machine and punching technology Any thermal cutting technique, except in a few cases where it can be started from the edge of the board, generally must have a small hole through the board. Before the laser stamping compound machine is to punch out a hole, and then start cutting from the hole with the laser. There are two basic ways to punch a laser cutter without a stamping device: Blasting perforation - The material is irradiated… Read More »BS3015T-3000W Laser cutting machine common six problems and treatment methods