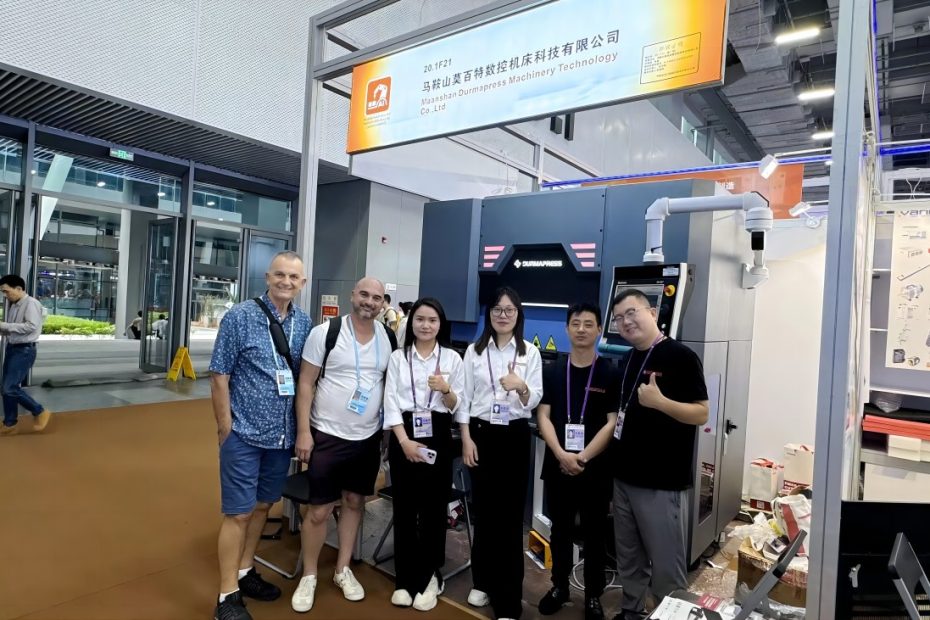

Durmapress Visits Clients in Mexico

During the FABTECH exhibition in Mexico, the Durmapress team embarked on an unforgettable journey to visit our long-standing clients. Engaging with our clients, we attentively listened to their genuine feedback and inquiries regarding product usage.