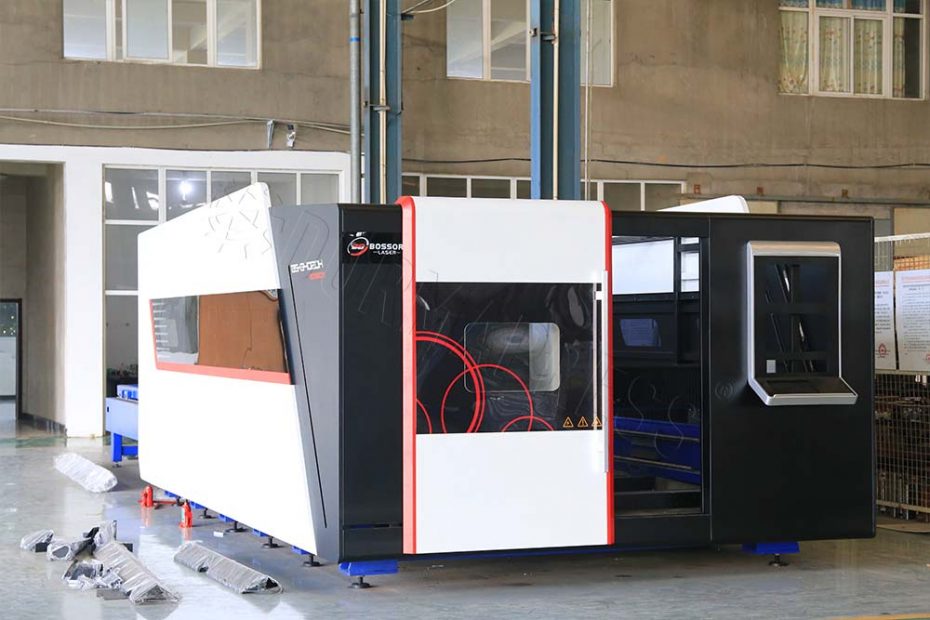

Rapid cost reduction and efficiency increase, 1000W laser cutting machine automatic feeding and blanking system has words

To process a product on a 1000W laser cutting machine , you first put the material you want to process on it, and then take it off. The traditional way of manual, now generally use automatic blanking system and feeding system, more intelligent solutions can let manufacturers quickly reduce production costs, improve production efficiency. What is the most expensive in the 21st century? Labor is the most expensive. Feeding and blanking is repeated heavy manual labor. In the whole production… Read More »Rapid cost reduction and efficiency increase, 1000W laser cutting machine automatic feeding and blanking system has words