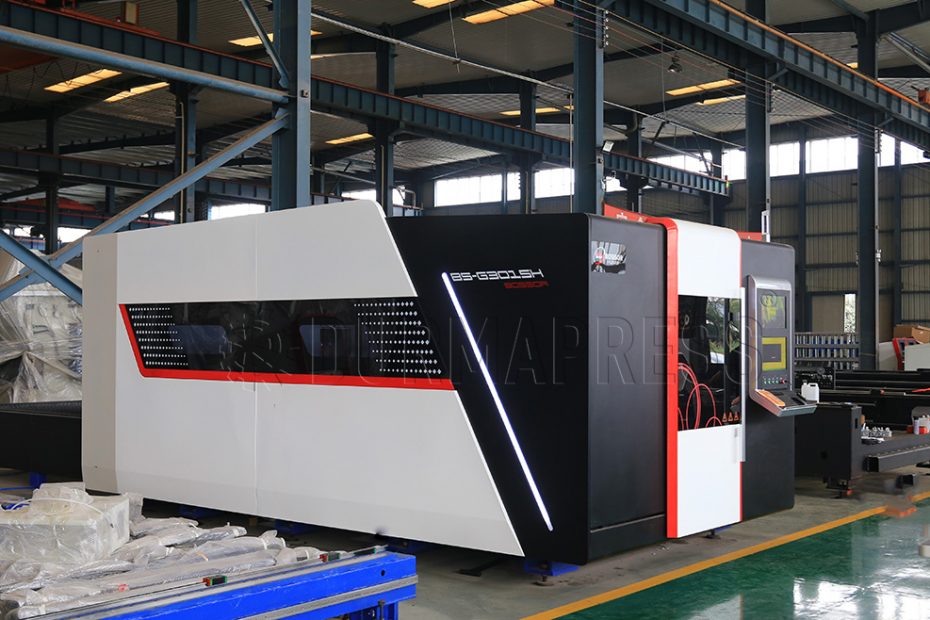

Precautions for starting the 1500W fiber laser cutting machine

After optical 1500W fiber laser cutting is shut down for a long time, in order to ensure an fully reliable operation of the equipment, extend the service time, and avoid unnecessary trouble caused by irregular startup for future use, the following steps should be followed before startup. 1. Start the main power supply and the voltage regulator power supply (before starting the power supply, check whether all lines are damaged or have poor contact) 2. Switch on the… Read More »Precautions for starting the 1500W fiber laser cutting machine